Vg 10 vs s30v

Hello Lurker! Remove this ad and much more by logging in. What's your favorite blade steel?

Post by Grego77 » Sun Feb 13, pm. Post by Tsujigiri » Sun Feb 13, pm. Post by dj moonbat » Sun Feb 13, pm. Post by Zenith » Sun Feb 13, pm. Post by psychophipps » Sun Feb 13, pm. Post by Blerv » Sun Feb 13, pm. Post by mongatu » Sun Feb 13, pm.

Vg 10 vs s30v

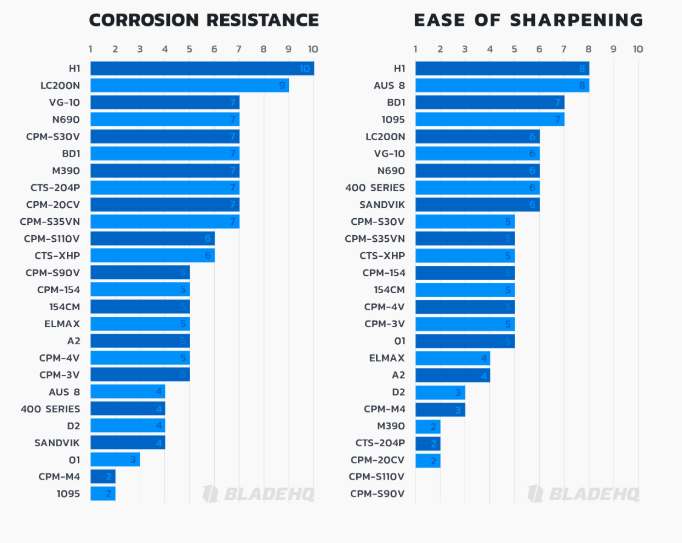

In this article, we will be taking a closer look at VG10 and S30V steel, two stainless steels widely used in the manufacture of most knives. VG10 is a high carbon, cobalt stainless steel that is known for its corrosion and edge retention, making it suitable for use in kitchen knives and pocket knives where a sharp edge is required. S30V is a high carbon stainless steel, but it is known for its excellent balance in edge retention, wear resistance, and corrosion resistance, making it a popular choice for use in pocket knives, outdoor and tactical knives. Both VG10 and S30V steels are considered premium steels and are generally more expensive than other types of stainless steel. The cobalt addition in VG10 Steel is one of its unique features. According to research Cobalt addition is aimed at improving the steel properties when tempered at higher temperatures. It is due to this cobalt addition that VG10 steel is able to be surface coated with coatings that require high temperature application without affecting the performance of the steel. VG10 steel is known for its edge retention, wear resistance, and corrosion resistance making it suitable for use in folding knives and kitchen knives. It is also regarded as a premium Japanese steel and is highly sought after by most knife enthusiasts and professionals. VG10 is commonly used in the manufacture of high-quality kitchen knives, pocket knives, and other cutting tools. S30V stainless steel is a premium steel known for its excellent balance of edge retention, wear resistance, toughness, and corrosion resistance. S30V steel is designed in such a way that it favors the formation of Vanadium carbides alongside chromium carbides. This is what makes S30V stainless steel unique from most other stainless steel as most stainless steel mostly contains chromium carbides, which are excellent for edge retention and wear resistance. Apart from the manufacture of knives CPM S30V steel is also used in the manufacture of Pelletizing equipment, Valve components, screws, dies, and in the food and chemical industries.

JR2ATN 1 post. What are the benefits of using Vg10 Steel? Both VG10 Steel and S30V steel are known for their average toughness, they are not the best stainless steels for tough applications as they may be susceptible to chipping and breaking, vg 10 vs s30v.

Vg10 Steel Vs S30v. When it comes to choosing the best steel for your projects, there are a few factors you need to consider. And this article Discoverthedinosaurs. Chromium makes VG10 steel resistant to corrosion, making it a great choice for projects that will be exposed to water or other elements. Some benefits of using Vg10 steel for your projects include its resistance to corrosion, strength, and hardness.

In this article, we will be taking a closer look at VG10 and S30V steel, two stainless steels widely used in the manufacture of most knives. VG10 is a high carbon, cobalt stainless steel that is known for its corrosion and edge retention, making it suitable for use in kitchen knives and pocket knives where a sharp edge is required. S30V is a high carbon stainless steel, but it is known for its excellent balance in edge retention, wear resistance, and corrosion resistance, making it a popular choice for use in pocket knives, outdoor and tactical knives. Both VG10 and S30V steels are considered premium steels and are generally more expensive than other types of stainless steel. The cobalt addition in VG10 Steel is one of its unique features.

Vg 10 vs s30v

One of the features that are often overlooked is the blade material. Two of the most popular steels for both outdoor carry and culinary uses are the VG10 and S30V. What is the difference between VG10 vs S30V steel? Note — While we focus on outdoor survival use cases, we also touch on culinary knives for those looking for a kitchen accompaniment.

Madridxtra

Search Advanced search. Some might say that S30V "stabilizes" to a working edge. It took some time for me to restore its initial razor sharp edge but it performed wonderfully. This was the first "brand" steel, it was released with unheralded fanfare and basically kickstarted the steel junkie fever. S30V steel is designed in such a way that it favors the formation of Vanadium carbides alongside chromium carbides. This makes vg10 steel stronger and more resistant to wear and tear, making it a better choice for projects that require heavy use or frequent bending. Both get very sharp and seem to hold an edge about the same in normal use. It's a great "real world" steel. If we didn't have access to the exotics I would be happy to have all my blades in either steel with a proper heat-treat. That makes the choice very personal, and particular answers depend on individual usage patterns. VG10 stainless steel is a popular choice for knives because it has a high carbon content, making it tough and resistant to corrosion. The average toughness in VG10 steel and S30V steel is due to the higher Rockwell hardness achieved and the presence of hard carbides in their composition.

This post may contain affiliate links. We may receive a commission from any qualified purchases at no extra cost to you.

S30v does hold a longer "working edge" when compared to VG Conversely, being a 'sharp-aholic,' I get a bit annoyed that S30V looses that initial edge so quickly, , , ,but really like how the good quality edge seems to have a lot of staying power. In this article, we will be taking a closer look at VG10 and S30V steel, two stainless steels widely used in the manufacture of most knives. I'd rather have a steel that will hold an edge longer and be more durable when I really needed it. S30v steel is a higher-grade stainless steel that offers better performance in these applications. It retains a good edge, it's pretty easy to sharpen, and it is relatively rust resistant. However, some food for thought, I think personally it all comes down to what you find easiest to sharpen if one is a new knife user. Both are excellent premium steels but each may be better suited for different types of applications. It took me a hour to get the edge back to sharp. None are available in both steels, so unless you're buying a knife just to get a certain steel, rather than buying it because you like the knife, you really don't have a choice. VG10 is a more newbie friendly steel offering good performance while still being easy to sharpen. Post by ChrisR » Sun Feb 13, pm. Users browsing this forum: Bluemoon69 , destroid , Enactive , Manixguy , mikey , miohin , SteveMidwest and 43 guests.

I consider, what is it � a lie.

What quite good topic