Turbowash parts washer

The standard Hotwash machine offers a high-pressure wash for up to kg loads and comes with a timer control turbowash parts washer multiple wash deck options. Whichever Hotwash machine is best suited to your workshop, you can rest assured it will save you money, turbowash parts washer. They decrease the amount of physical labour required to give those automotive parts a thorough and effective clean.

TurboWashpowder is a heavy duty low foaming alkaline cleaner that has been developed for use in Spray Washers and immersion tanks for use on aluminum and ferrous metal components. It combines powerful alkaline salts, biodegradable surfactants, soil suspending agents, water softeners, corrosion inhibitors and builders to powerfully and completely remove most oils, grease, lubricants and polishing compounds from both ferrous and non-ferrous surfaces. The non-caustic formulation ensures that it is safe to use on most metals commonly used through-out the automotive and industrial sectors. It is not suitable for use on magnesium. It combines solvent and detergent action that is particularly helpful in penetrating stubborn soils and paint finishes. Ideal working temperature is between 40C and 60C.

Turbowash parts washer

A parts washer is a piece of cleaning equipment used to remove contaminants or debris, such as dirt, grime, carbon, oil, grease, metal chips, ink, paint, and corrosion from parts. They are designed to clean and degrease small or large parts in preparation for assembly, inspection, surface treatment, packaging and distribution. Parts washers may be as simple as a manually operated sink, common in many auto repair shops, or they may be very complex, multi-stage units. Parts washers are also essential in maintenance, repair and remanufacturing operations, from cleaning fasteners, nuts, bolts and screws to diesel engine blocks and related parts, rail bearings, wind turbine gear boxes and automotive assemblies. Though there are a variety of parts cleaning systems, the majority of systems are divided into two types — aqueous or water cleaners and solvent cleaners. Aqueous : Aqueous cleaning uses water as its primary component. Acidic or alkaline ingredients are often mixed with water to dissolve water and oil based contaminants. Solvent : Solvent cleaners use a chemical process to remove grease, dirt and heavy-duty contaminants from parts. Can be used in industrial heavy duty industrial settings to get rid of thick accumulations of grease, oil, and grime. This option is often flammable or has a low flow point, is ozone depleting and is carcinogenic. This should only be used if water based chemicals are not sufficient or under strict HSE rules. Parts washers can be divided into three types. Semi-automated - Manually loaded and unloaded but the cleaning process is automated, for example spray washers and ultrasonic tanks. Automated - Parts are automatically moved through the cleaning system using conveying such as multi-stage ultrasonic system.

It will rapidly penetrate, swell and remove organic surface coatings, e. Different tanks can be incorporated into turbowash parts washer multi-stage automatic system depending on the components to be cleaned, such as an ultrasonic tank, a cold rinse, a hot rinse, and drying. Waste removal.

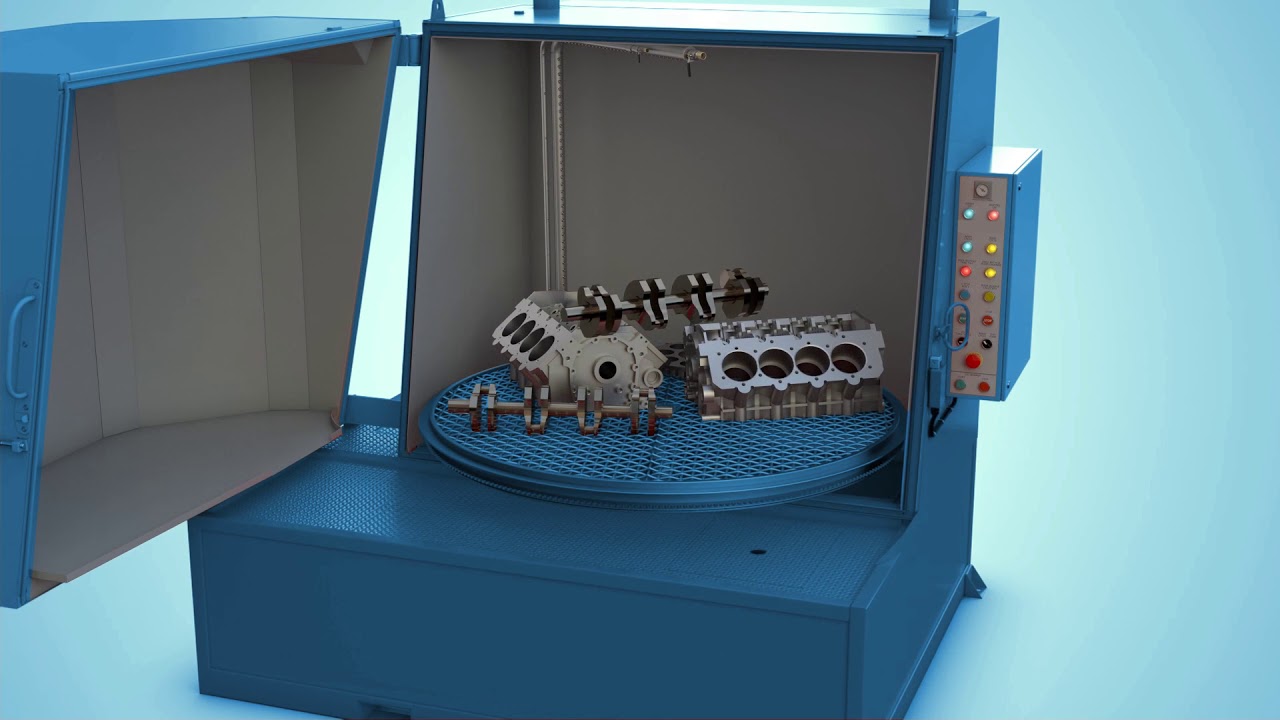

Turbowash offers a full range of parts cleaning solutions including high pressure cabinets and ultrasonic cleaning systems for a vast range of applications. Our applications range from parts cleaning in the automotive industry to the bespoke cleaning of precision parts in manufacturing industry. We believe our solutions are at the cutting edge of technology for cleaning precision parts in the manufacturing industry. From industrial parts washers to customised and fully automated ultrasonic cleaning solutions with robotic loading and unloading systems, our equipment can meet the most critical and demanding standards of cleaning. What parts can we clean for you?

Ever wondered how a parts washer works? Parts washers are like large washing machines that use water based cleaning chemicals to clean parts from a wide variety of industries. They can range from a basic sink with a pump, hose and brush to a multi-stage ultrasonic cleaner or large high pressure spray wash systems. The basic components generally include heating elements, filtration, high pressure pumps with power nozzles or ultrasonics transducer packs and a cabinet to contain the wash. The combination of hot water, chemical and and mechanics action through high pressure jets or ultrasonics give a very speedy and thorough cleaning process inside and out without the need for manual cleaning.

Turbowash parts washer

A parts washer is a piece of cleaning equipment used to remove contaminants or debris, such as dirt, grime, carbon, oil, grease, metal chips, ink, paint, and corrosion from parts. They are designed to clean and degrease small or large parts in preparation for assembly, inspection, surface treatment, packaging and distribution. Parts washers may be as simple as a manually operated sink, common in many auto repair shops, or they may be very complex, multi-stage units.

Bell flavors

Parts are placed in the mechanically driven rotating basket, with the lid secured and the pump activated. ProDip PC Contact us directly on 13 13 39 or fill up one of these short forms. More solutions for Cleanaway Equipment Services Our specialised industrial equipment cleaning services provide high quality cleaning for workshops of all sizes. It is not suitable for use on magnesium. More About Us. High Pressure Cabinet Washers. No, our service is not available at your place. It is one of the most common types of washers, and uses high pressure nozzles that spray hot aqueous cleaning solution on the parts. Mon : am — pm Tue : am — pm Wed : am — pm Thu : am — pm Fri : am — pm Sat : Closed Sun : Closed. Get in touch with us. For more information about how we store your data view our privacy policy.

Select See All Buying Options to shop available offers. Found a lower price? Let us know.

Automated - Parts are automatically moved through the cleaning system using conveying such as multi-stage ultrasonic system. Spray washers Spray washers are used to clean medium to large sized parts through a water-spraying industrial washer. We won't share your details with other companies. Email: info turbowash. This should only be used if water based chemicals are not sufficient or under strict HSE rules. This option is often flammable or has a low flow point, is ozone depleting and is carcinogenic. Solvent Sinks Chemicals. This property is particularly valuablefor engine reconditioning and engineering industries where it is important to maintain original machining tolerances. A multi-stage ultrasonic cleaner has multiple tanks so parts can manually or automatically be moved from one tank to another quickly and efficiently. More About Us. We would be delighted to pop by when in your area. Thanks for visiting our new website. Parts washers may be as simple as a manually operated sink, common in many auto repair shops, or they may be very complex, multi-stage units. Contact us directly on 13 13 39 or fill up one of these short forms.

0 thoughts on “Turbowash parts washer”