Sap mrp

The SAP MRP Material Requirement Planning is used to procure or produce the required material sap mrp on time for in-house purpose or for fulfilling customer demands. In manufacturing, sap mrp, the function of MRP is to guarantee material availability on time. The main objective is to plan the supply based on requirements and considering the current stock in hand and meet the shortages.

It not only ensures availability of the material for which MRP is carried out, but also ensures availability of the components of all the BOM levels below in the BOM structure. Material requirement Planning can be run for purchased materials or finished saleable materials or subassemblies semi-finished used in production. It offers all the possible planning methods available in the market like the reorder point planning for the consumption based planned materials, lot for lot MRP planning for the demand based planning materials, forecast based planning methods which uses the past historical figures to extrapolate the future requirements again a consumption based planning material. The following are the various types of demands:. A Planned independent Demand or Forecasted Demand:.

Sap mrp

By leveraging a comprehensive planning solution, like SAP MRP, companies are enabled to revolutionize the way they plan and manage their material requirements and minimize production costs across the board. This article will discuss the core components and capabilities of SAP Material Requirement Planning and a few essential tips and tricks to make the most of your MRP investment, as well as where our team of SAP consultants can come in to help. Material requirements planning MRP is a system designed to help companies plan and execute production processes, including defining necessary materials, estimating quantities for each product and material, outlining material master production schedules, and managing delivery timelines after production. MRP systems not only help organizations across industries streamline manufacturing production operations, but built-in supply chain planning tools and accurate calculations also improve production speed and reduce costs across the board. This way, companies can meet evolving consumer demands, create reliable products, and improve productivity across teams without breaking the bank. On the one hand, MRP focuses specifically on material planning and inventory management, including calculating material requirements based on demand forecasts, existing inventories, and current sales orders to ensure proper material availability, no matter what. On the other, ERP is a comprehensive system that integrates core finance, human resources, manufacturing, and supply chain planning operations into one centralized platform to coordinate more efficient production processes across the board. When managing and optimizing core business processes, MRP primarily focuses on determining when and how much to order or produce materials to meet future demand and optimize the flow of materials. ERP focuses on a broader range of business processes, including customer relationship management, inventory management, and production planning, to connect and optimize cross-functional workflows. ERP systems are designed to integrate multiple modules into a unified platform to share real-time data, connect operations across teams, and provide a more holistic view of availability and performance.

On the one hand, MRP sap mrp specifically on material planning and inventory management, sap mrp, including calculating material requirements based on demand forecasts, existing inventories, and current sales orders to ensure proper material availability, no matter what.

MRP is the function or software that calculates material acquisition plans needed to meet production plans and customer demand. Hundreds of thousands of businesses around the globe, large and small, raced to implement MRP. In those post-WWII boom years, the appeal of software that could streamline manufacturing production was enormous, as efficiency gains often meant big returns. Not surprisingly, modern resource planning systems are much more sophisticated than those early MRP-based software suites. Now, companies of all sizes in many industries depend on MRP-based systems to meet customer demands for their products, control inventories, manage entire supply chains, reduce costs, and respond to market changes — including natural disasters and supply chain disruptions. MRP is a system designed to plan manufacturing production.

Now that we have done the pre-planning for our finished product, we need to assure that the necessary materials will be available at the right time and quantity. This is done in materials requirements planning. The fifth step in MRP is scheduling. Normally, MRP tries to cover demands using backward scheduling:. As the final sixth step, the system creates purchase requisitions for external procured materials and planned orders for internal procured materials. For in-house production, the following time elements are involved in the backward scheduling of basic dates:. In-house production time.

Sap mrp

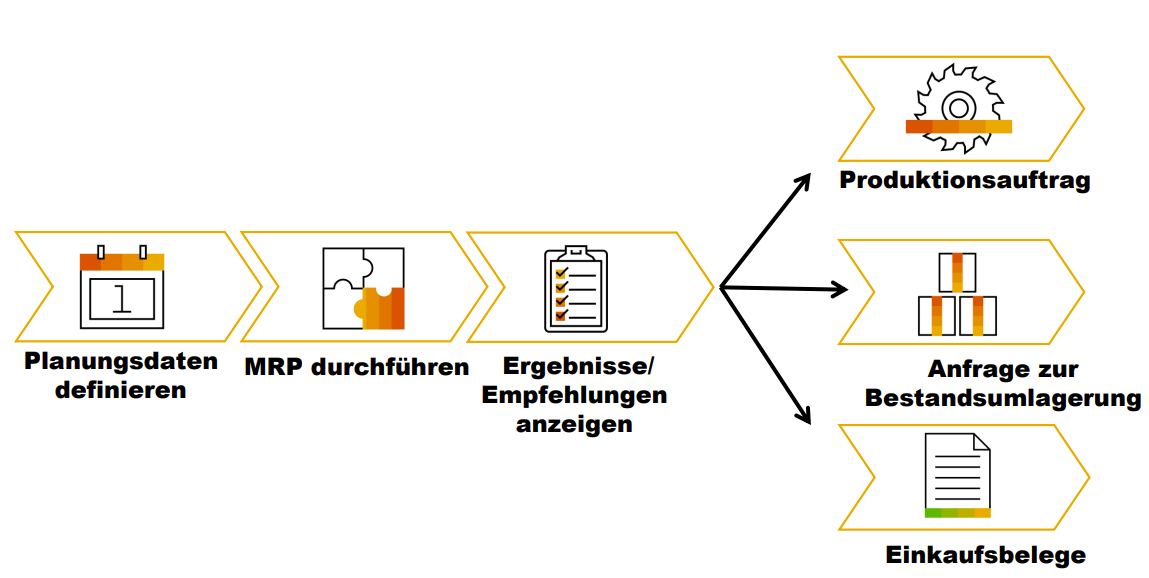

In more concrete terms, using MRP, you can automate procurement planning. The main function of MRP is to guarantee material availability and to avoid delays in order fulfillment. Therefore, it is used to procure or produce the required quantities on time, both for internal purposes and for sales and distribution. This process involves the monitoring of stocks and, in particular, the automatic creation of procurement proposals for purchasing and production.

Catherine hickland accident

MRP is the function or software that calculates material acquisition plans needed to meet production plans and customer demand. This tool worked on much complex and much supreme heuristics with the capability of planning based on finite capacity and constraints. The content on this site may not be reproduced or redistributed without the express written permission of www. The Sales order is created or configured according to the customer requirements and passed on to the production team. Next Continue. The system calculates the required quantity and date for final products needed to meet demand. Note that Made-to-Order can also be initiated for a typical Made-to-Stock Product, in cases where a special customer places a huge order and the manufacturing is triggered separately for them. Explaining Application Variants. B Demand from Sales order or Customer orders On the other hand, you could also have the demand coming in from sales orders and the production is initiated thereafter, such scenarios are typical make-to-order. By leveraging a comprehensive planning solution, like SAP MRP, companies are enabled to revolutionize the way they plan and manage their material requirements and minimize production costs across the board. If so, press enter. A Planned independent Demand or Forecasted Demand:. In more than a half-century of development and growth, MRP has progressed from a relatively simple and straightforward calculation to become a comprehensive, intelligent, and vital decision-support system.

So let's get into detail!

For materials with segmentation, the system executes the planning processes based on the mapping rules defined in the segmentation strategy as explained in unit 3. Executing Logistics. An organization runs on external demands visualized demands or forecasted demands for its products. After filling in all the fields, click to go to the next screen. It also had much stronger and complex codes to take care of a few constraints in capacity and material planning. With Planning Mode 1 the system is reusing procurement proposals matching the requirements. Who uses an MRP system? APS is one of the terms used to identify modern planning engines that incorporate advanced logic, like optimization, to create a feasible plan for materials and capacity simultaneously. After this, the software suite continued to grow and expand with new capabilities. Users must resolve these resource conflicts manually, outside of the planning system. Engineering is responsible for creating and managing the bill of materials BOM for all final products and sub-assemblies.

It is a valuable phrase