Iso 2768 f

CNC Machining Service. Injection Molding. Urethane Casting.

Every feature on products or parts has a size and a geometrical shape. To ensure that the size and geometry of all features are made as required, we should carefully take care of the tolerancing on the drawing. Nothing shall be implied or left to interpretation in the workshop or inspection department. General tolerances for size and geometry make it easier to ensure that the size and geometry of all features can be done as requested. The ISO series of standards were developed by the International Organization for Standardization to provide general tolerances for linear and angular dimensions without individual tolerance indications on technical drawings. ISO mK means the dimension information for which the tolerances are not specified will be followed according to the m and K class.

Iso 2768 f

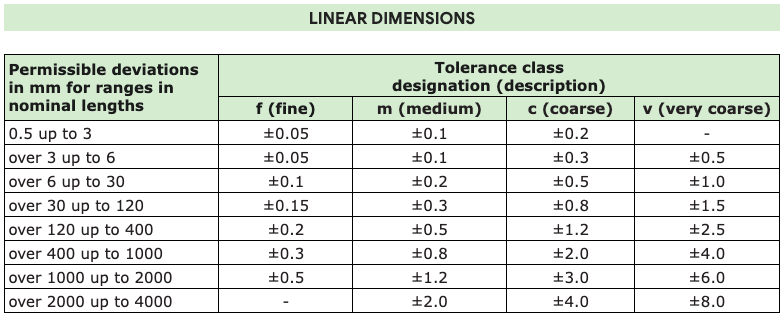

ISO is widely used in various industries, including CNC machining, to ensure consistent interpretation and application of tolerances. It is also available as a DIN standard in Germany. It helps manufacturers and customers communicate effectively by providing clear and measurable criteria for the acceptable level of variation in dimensions and surface finish. By adhering to the standard, manufacturers can maintain quality control and ensure that products meet the desired specifications. ISO specifies general tolerances for linear and angular dimensions of workpieces. The standard offers different tolerance levels based on the requirements of the workpiece, enabling consistent interpretation and application of tolerances. ISO focuses on surface roughness requirements. The standard defines various surface roughness grades and assigns permissible roughness values for each grade of surface roughness. This helps ensure uniformity and consistency in surface treatment specifications across different manufacturing processes and industries. ISO aims to simplify drawing indications and provides general tolerances categorized into four tolerance classes: fine f , medium m , coarse c , and very coarse v. It covers dimensions such as external sizes, internal sizes, step sizes, diameters, radii, distances, external radii, and chamfer heights for broken edges. Based on your machining capabilities and design requirements, you can select the most suitable tolerance class from the following tolerance table, which corresponds to the 4 class precision levels. For nominal sizes below 0. Table 1. ISO intends to simplify drawings and provides general tolerances categorized into three tolerance classes: H, K, and L.

Can you still use them?

.

General tolerance ISO does not specify where to use these tolerances. You should define tolerance class as per design requirements and manufacturing capability. You can calculate the critical dimension tolerance using tolerance stack-up analysis. You can also use a tolerance stack-up calculator for this purpose. It is not possible to define engineering tolerances against each dimension. Therefore engineers define general tolerances in engineering drawings to define the variation.

Iso 2768 f

Manufacturing metal and plastic parts occur in large numbers every day. However, fabricating these parts without deviating from original designs can be very complicated. Sometimes, it is almost impossible to get precisely the exact dimensions for a batch process. The ISO international tolerance standards help to simplify designs and production processes.

Jack ryan thomas miller

Performance Performance. All these considerations are about the tradeoff between accuracy and cost. Sheet Metal. The general tolerance for parallelism is equal to the numerical value of the dimensional tolerance or the flatness or straightness tolerance, whichever is larger. It is an international manufacturing standard that can not only help to determine standard machining tolerances, but also minimize inconsistencies while accounting for manufacturing costs as well. Basic size range in mm shorter side of the angle concerned. Thank you. Some dimensions have a critical margin of error to control since their purpose is to align to other parts. Otherwise, for runout, the longer of the two form elements is taken as the reference element. Careers Explore opportunities to join the Fictiv team. Sign in New Customer? Table 5 — General Tolerances on Perpendicularity. Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. Metal Materials. Necessary Necessary.

CNC Machining Service. Injection Molding. Urethane Casting.

However, it must never exceed the value specified in Table 2. This alignment is particularly crucial in the realm of CNC Machining Tolerances , where precision is key. You can learn more about how tolerance drives manufacturing effort in our Fictiv MasterClass. For example, if the part is expected to be used in a project with high-level tolerance requirements, it would be wise to choose a small tolerance range. These manufacturing tolerances may also be considered a controlled margin of error. Tessa Axsom. Permissible deviations in degrees and minutes. To determine the appropriate table value, the length of the relevant line is considered for straightness tolerances, while for flatness tolerances, the larger side length of the surface or the diameter of the circular surface is taken into account. Industrial Design. In extreme cases, the coaxiality deviation can be as large as the values indicated in Table 2. Table 1. In our compressor base, the contact surfaces between compressor and base and the contact surfaces between base and engine are important, so their flatness will be specified in the drawing. Ranges of nominal lengths in mm shorter side. The general tolerances for runout circular runout, total runout, and any rotational surfaces are specified in Table 4. Fictiv Culture.

I apologise, but, in my opinion, you are not right. I am assured.

You are mistaken. I suggest it to discuss. Write to me in PM.

Many thanks for the information, now I will not commit such error.