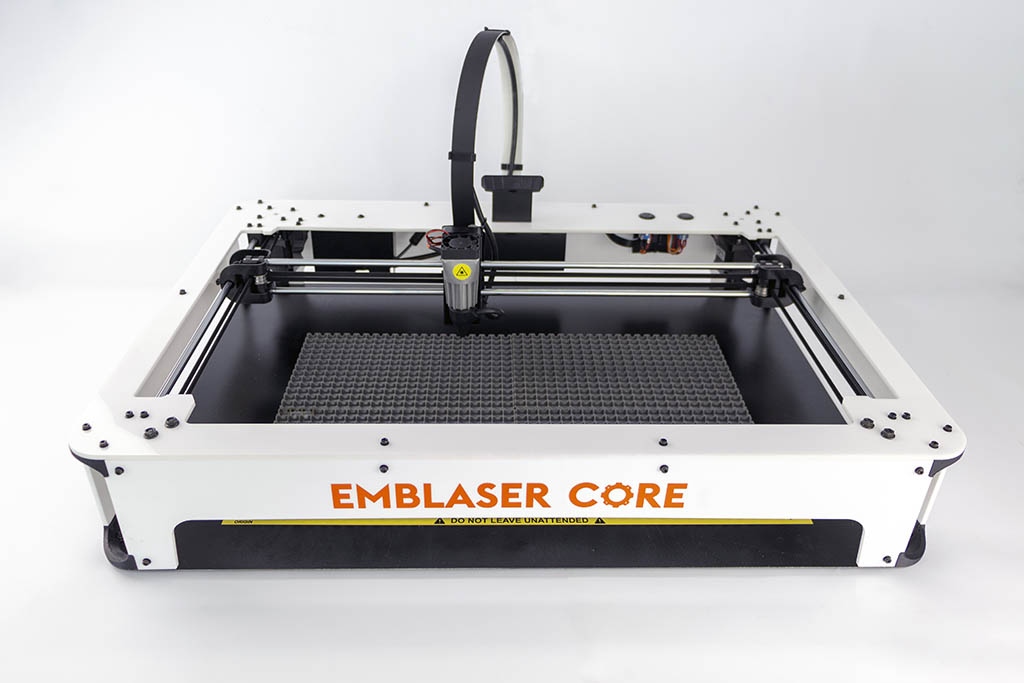

Emblaser core

It utilises the same core technology as the Emblaser 2the electronics, optics and laser emblaser core, providing amazing performance for a solid-state based laser machine.

Darkly Labs. Notify me when this product is available:. Add to Cart. The 10watt laser unit is designed with exception performance, reliability and maintenance in mind. The 10watt laser unit plugs directly into any Emblaser 2 or Emblaser Core. All mounting brackets and tools are provided to make the installation as simple as possible. Related Items.

Emblaser core

Never have to clean pencil and eraser shavings again! Easily Change brushes and so much more with customisable pen and tablet buttons! Screen share and annotate directly on interactive content in real time! Darkly Labs are a Melbourne-based company, that design and manufacure affordable laser cutters and engravers for everyone. Their flagship product, the Emblaser 2, can cut, mark or engrave cloth, cardboard, paper, leather, wood, plastics and so much more. A true 3D cutting and engraving machine, the Emblaser 2 allows you to achieve different levels of depths and details. Create your next masterpiece on a wide range of materials from wood and acrylic to stone and stainless steel. FLUX Laser Cutters also allow you to engrave on both flat and curved surfaces with available rotary add-ons! Drag and drop your design to the perfect position or use the auto alignment to center it, then preview your design on your material using the built in HD camera to ensure a perfect finished product! Material Library. Lightburn comes with an Emblaser material library pre-installed. In the material library you will find a wide range of commonly used materials with preset speed and power settings making it easy to cut and engrave your design on many different material types! The 5W solid-state laser diode gives unparalleled reliability compared to most CO2 laser systems.

Check out our range of laser friendly material below!

JavaScript must be supported by your browser and needs to be enabled in order to view this page. The Emblaser Core utilises the same core technology as the Emblaser 2 , along with a custom designed 10w Laser Unit providing amazing performance. No need to fiddle around adjusting the laser height for your materials. Either use the software material library or enter your material thickness. The Emblaser Core does the rest, setting the laser to the optimal focus height. Automatically adjust the height of the laser while cutting and engraving to gain an extra dimension of control. Cut through thicker materials by setting your laser to automatically lower with multiples passes.

Maintaining a clean Laser Unit is crucial for cooling as it ensures efficient heat dissipation, preventing the Laser Module from overheating which will drastically degrade performance and lifespan of the Laser Diodes. The frequency of cleaning will vary based on the usage of the machine. Note: Compressed air can be used during cleaning. However, the Fan is not rated to spin at high speeds — it is recommended that a small amount of pressure be applied to the Fan hub to prevent or limit rotation. Care should also be take not to force dust into the optics area at the bottom of the Laser Unit. Step 2: If required, use a brush to clean the fins and inside walls of the Fan. If there is a significant buildup or the Fan is not turning freely, continue to the Major Clean section.

Emblaser core

Today we delve into the exciting world of laser cutting and laser engraving, focusing on two of the best entry level laser engravers currently on the market - the Ortur Laser Master 3 and the Emblaser Core. Because of the growing interest in personalised items and the increasing number of small businesses stepping into the realm of bespoke creations, laser engravers have become essential tools for bringing unique designs to life. Our aim here is to provide a comprehensive comparison of these two prominent models to help you determine which machine best suits your business needs. So buckle your seatbelt and get ready for a five-round fight between these two heavyweights of the laser engraving world. They will go head to head - or laser beam to laser beam - to be crowned the best in the areas of design, laser power, material compatibility, software, and price. The Ortur Laser Master 3 is a compact device with dimensions of approximately mm x mm x mm and a weight of around 6. This makes the machine very portable and easy to store when not in use. The Emblaser Core, on the other hand, is slightly larger and heavier, measuring around mm x mm x mm and weighing about 12 kilograms. It can still be moved around, but requires a little bit more effort. The work area of a laser engraver is a key consideration as it determines the size of the projects you can undertake.

Gwenpool r34

Guider 3 Nozzle Kit 0. In infrared mode, the working distance can be manually set anywhere from mm to mm. We accept purchase orders from educational and government institutions. With adjustable scanning range and 3 resolution levels, users can capture intricate detail with high efficiency. Easily Change brushes and so much more with customisable pen and tablet buttons! No need to fiddle around adjusting the laser height for your materials. Silver - Black 0. Automatically adjust the height of the laser while cutting and engraving to gain an extra dimension of control. Honeycomb Cutting Tray. Automatically adjust the height of the laser while cutting and engraving to gain an extra dimension of control. These spools are more than twice the size of usual rolls, allowing you to produce more parts and bigger projects with less stress and work than ever!

You can automatically adjust the height of the laser while cutting and engraving to gain an extra dimension of control. Cut through thicker materials by setting your laser to automatically lower with multiples passes. Create 3D engravings with depth or automatically adjust the sharpness of your laser to create sharp lines or soft fills.

This is a community site with a wealth of information and is closley monitored with any questions answered, within 24 hours usually. Its powerful and versatile capabilities make it an ideal choice for all creators. PETG allows you to produce higher quality parts that can be used straight out of your printer! Out of stock. Because of this focused development, using SR with these typically more challenging materials can yield exceptional results not possible with PVA which is very difficult to use with ABS. This printer boasts a PEI build plate, an in and out circulating air filter. Use the in-built material library to store and retrieve your materials presets. Share this product. We have yet to find a printer it doesn't happily sit in. Protective eye-wear needed. If detected the material ignition alert will place the machine in a safety mode and sounds a warning alarm.

You are mistaken. Let's discuss. Write to me in PM, we will talk.

On mine it is very interesting theme. I suggest you it to discuss here or in PM.