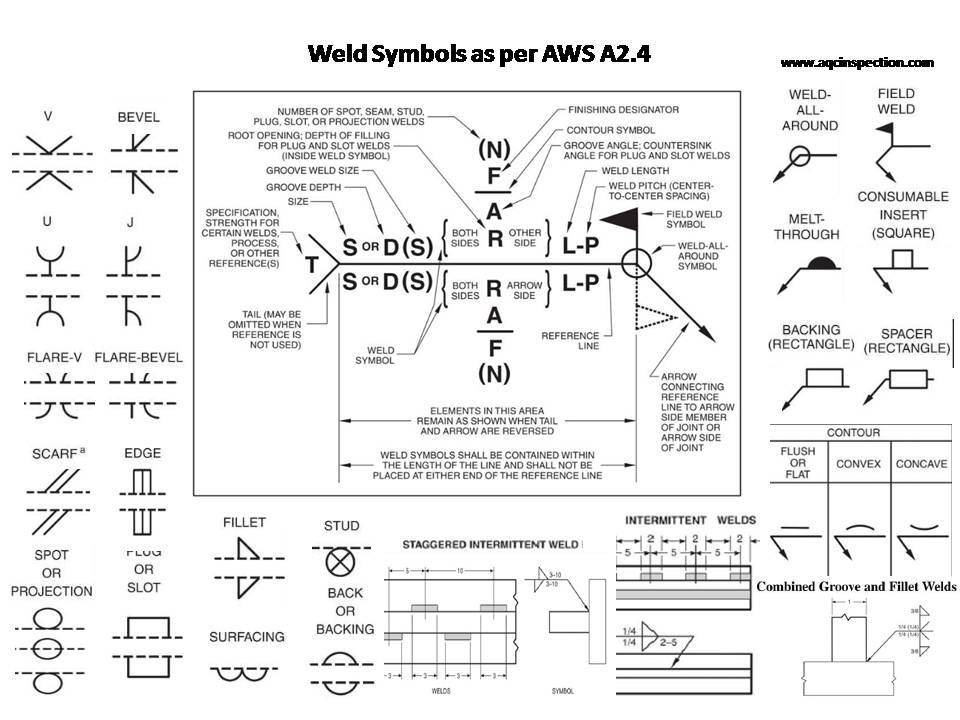

Welding symbols chart

Next to Welding Certification Welding symbols are one of the most misunderstood concepts in the welding profession.

It should be understood that these charts are intended only as shop aids. The only complete and official presentation of the standard welding symbols is in AWS A2. Suitable for framing or displaying on your shop wall, the welding symbol chart is 11 x 17 inches. Click on the image to download the full size chart. With this chart, you can easily convert between fractional, decimal, and metric sizes for all of your shop needs! Suitable for framing or displaying on your shop wall, the decimal chart is 11 x 8.

Welding symbols chart

This guide will help you to understand different welding blueprint symbols and signs. We will point out the weld callouts with example images and list of options for each aspect of the welding symbol. When designing parts for general metal fabrication, welding symbols, and detailed callouts will be required to communicate design intent and requirements effectively to manufacturers. These callouts will be found on the technical drawings or blueprint of the assembly, also known as a weldment, and will specify weld geometry and its associated size and length requirements. When interpreting a print, the welding symbol will contain all the appropriate information necessary to perform the proper weld on the part. Welding symbols, which are different than weld symbols, contain information such as what weld symbol is being used fillet, bevel, square butt, plug weld, etc. Welding symbols are a menagerie of information, and the combinations of designs and choices that can be made are significant. Example of basic welding symbols. Types of Welding. There exist a variety of welding processes to utilize, but ultimately welding processes are generally agnostic to the process, so long as the symbol callouts are satisfied during the fabrication process. Weld Procedures are generated and used if specific welding processes are required, and these go even further to specify the filler material, any preheat requirements for the part, as well as heat input and feed rates allowed during the welding process. All of these common forms of welding are doing via a handheld torch and allow the welder to create welds per the specific welding blueprint for the particular weldment being created. Welding Symbols. Welding symbols, also referred to as weld callouts and welding drawing symbols, contain information pertinent to the weld as previously mentioned. Below is a comprehensive list of what one can expect to see on a welding symbol, as well as an example image and list of options for each aspect of the welding symbol.

Products Shop Welding Accessories. E stands for the effective throat of the weld and is most used in groove welding.

.

Last Updated on Jul 17 Do you need to study on the run? Download the symbols chart as. PDF here. Becoming a professional welder is rewarding and provides a lifelong opportunity to enjoy fulfilling employment worldwide. There are many challenges along the way, and most are practical skill-based challenges.

Welding symbols chart

Material Welding. Weld symbols are a key part of welding documentation, and understanding How to read Weld Symbols is critical for welders. There are three main elements to a weld symbol:. The reference line is a horizontal line that is used to align the other elements of the symbol. The arrow is used to point to the location of the weld, and the tail contains information about the type of weld, size, and other details.

606mm to inches

When referring to the Basic Weld Symbols chart, note the different potential groove geometries and their visual representation of them. Without a subpoena, voluntary compliance on the part of your Internet Service Provider, or additional records from a third party, information stored or retrieved for this purpose alone cannot usually be used to identify you. The Arrow Head The head of the arrow is used to point directly to the spot that is expected to be welded on the blueprint. The length of the weld is given to the right of the symbol. Finishing The finishing callout is directly related to the contour callout and specify which process will be used to achieve the desired contour. Would you prefer to share this page with others by linking to it? Additionally, weld metal specifications and standardized symbols for weld joints are indispensable for ensuring that the correct amount of material is used and that the proper joint configuration is achieved. In summary, welding blueprint symbols and signs serve as a vital communication tool in product design and mechanical engineering, enabling professionals to effectively represent various types of welds and weld joints on technical drawings. The only complete and official presentation of the standard welding symbols is in AWS A2. The Reference Line The reference line contains the bulk of the information about the weld. Bevel angle determines the overall effectiveness of the welder and their ability to get good penetration on their weld for proper welds to be formed. The Arrow The arrow is used to locate the location of the weld, and has the reference line attached to its body.

Material Welding.

If notations are not used, the tail of the symbol may be omitted. Download the poster Suitable for framing or displaying on your shop wall, the welding symbol chart is 11 x 17 inches. When interpreting a print, the welding symbol will contain all the appropriate information necessary to perform the proper weld on the part. The Bevel Angle The bevel angle is the shape of the bevel between the two connecting parts at the weld joint. The Arrow Head The head of the arrow is used to point directly to the spot that is expected to be welded on the blueprint. Accept Deny View preferences Save preferences View preferences. The truth is, depending on what kind of job you have, you might only have to know a small handful of welding or weld symbols. The edges of both pieces are chamfered, either singly or doubly, to create the groove. Furthermore, field weld symbols, denoted by a flag extending from the horizontal line, play a critical role in specifying that a weld should be executed in the field or on-site, as opposed to in a controlled shop environment. The technical storage or access that is used exclusively for statistical purposes. By far the two most important weld symbols to know are the fillet weld symbol and the groove weld symbols. You may also like Go ahead, explore our blogposts on different topics related to manufacturing and metal fabrication.

In my opinion you are mistaken. Let's discuss it. Write to me in PM.

All not so is simple, as it seems

This message is simply matchless ;)