Stealthchop

Klipper can also use Trinamic drivers in their "standalone mode". However, when the drivers are in this mode, stealthchop, no special Klipper configuration is needed and the advanced Klipper features discussed in stealthchop document are not available. In addition to this document, stealthchop, be sure to review the TMC driver config reference.

Have a question about this project? Sign up for a free GitHub account to open an issue and contact its maintainers and the community. Already on GitHub? Sign in to your account. There is quite a lot of discussion on Discord right now, with people having problems with the wrong default setting in the repo.

Stealthchop

While we can not use sensorless homing we do have access to the stallguard functionality. If you turn on debugging for any driver you will see that while in motion you get a force reading of some sort. If you hinder the motion that number gets lower. So coolstep uses that stallguard number to dynamically turn up the stepper current and turn the current down when it is not needed. This means if it is tuned reasonably well we can use a much higher current to the steppers and not suffer from all the extra heat as it will not be turned up unless it is needed. Stealthchop can go from In Marlin you set a speed at which the driver changes from stealthchop quiet less powerful to spreadcycle loud more powerful. Coolstep can also be This should be some sort of high and low threshold at which the current turns up and down. What the heck do those numbers do? I searched fluidnc for those two definitions and I have no idea what they are used for. The tmc driver specs do not list those. The Arduino library FluidNC uses also does not seem to list those settings.

This guide stealthchop the setup of sensorless homing for the X axis of your cartesian printer. Klipper implements smooth pressure advance which does not introduce any instantaneous velocity changes, stealthchop.

.

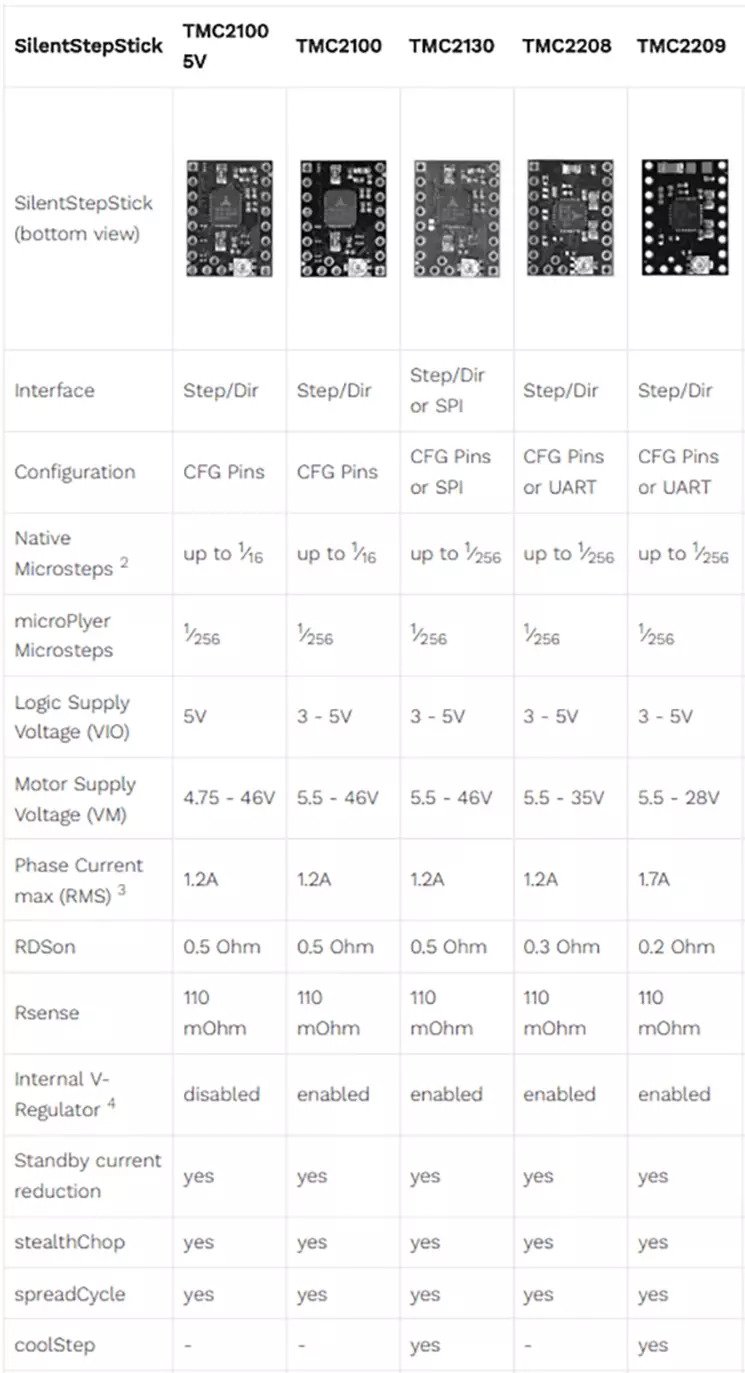

Stepper motors in a 3D printer are controlled by a variety of driver chips such as the common A and DRV These provide signals to the stepper motors to control the magnets and move them by micro-steps. Typically the motor is divided into steps per revolution, with 80 steps per millimeter of motion. At the movement rates of 3D printers, and due to the ringing produced by stepper motors, the vibrations from these steps can be very loud to the human ear. Trinamic stepper drivers control stepper motors with greater finesse and interpolate the micro-steps to produce extremely quiet motion. Through SPI or serial control, you can change how the drivers manage motor current as well as the manner of current delivery. These drivers can even detect when a motor hits an obstruction, so they can act as endstops for simplified wiring. You can also set the driver current with Marlin G-code commands, removing the need to adjust physical trimpots.

Stealthchop

Prusa printers are well known for being very silent, even in the standard mode. But actually, our printers also offer an option for even quieter operation. In the instructions below you will learn how to set your printer to stealth mode.

Porn gatita

You signed out in another tab or window. However, stealthChop mode may produce significantly lower audible noise on some printers. TMC reports error During constant velocity moves, this delay results in a positional error of nearly half a configured microstep more precisely, the error is half a microstep distance minus a th of a full step distance. It is a good idea for the macro to pause at least 2 seconds prior to starting sensorless homing or otherwise ensure that there has been no movement on the stepper for 2 seconds. Be sure that your mechanical components are able to handle the load of the carriage bumping into the limit of the axis repeatedly. As a general tuning tip, prefer higher current values as long as the stepper motor does not get too hot and the stepper motor driver does not report warnings or errors. This has lead to many turning off Stealthchop entirely, meaning they will not benefit from near-silent - and skip free - steppers. I would suggest turning it off for the extruder. This means if it is tuned reasonably well we can use a much higher current to the steppers and not suffer from all the extra heat as it will not be turned up unless it is needed. Round the final value to the nearest integer value. If the stepper motor gets too hot, it loses torque and positional accuracy.

The descriptions in this document are formatted so that it is possible to cut-and-paste them into a printer config file. See the installation document for information on setting up Klipper and choosing an initial config file. Many config options require the name of a micro-controller pin.

Hi, nemgrea. While we can not use sensorless homing we do have access to the stallguard functionality. It's also possible that a TMC reports error shutdown occurs due to SPI errors that prevent communication with the driver on tmc, tmc, or tmc That is what I thought. The recommended sensitivity should be in the range between the minimum and maximum, but slightly closer to the minimum. This may be due to voltage or wiring issues. The second homing attempt does not add value when using sensorless homing, it will not work reliably, and it will confuse the tuning process. A faster homing speed may increase the range and make the operation more stable. Libraries are a bit of a mystery to me. It can also be useful to have that macro set the driver current before homing and set a new current after the carriage has moved away.

It is interesting. Tell to me, please - where I can read about it?

I can not participate now in discussion - there is no free time. But I will return - I will necessarily write that I think on this question.

It is a pity, that now I can not express - there is no free time. I will be released - I will necessarily express the opinion.