Solidworks mcmaster add in

Forums CAD Models Blogs 3.

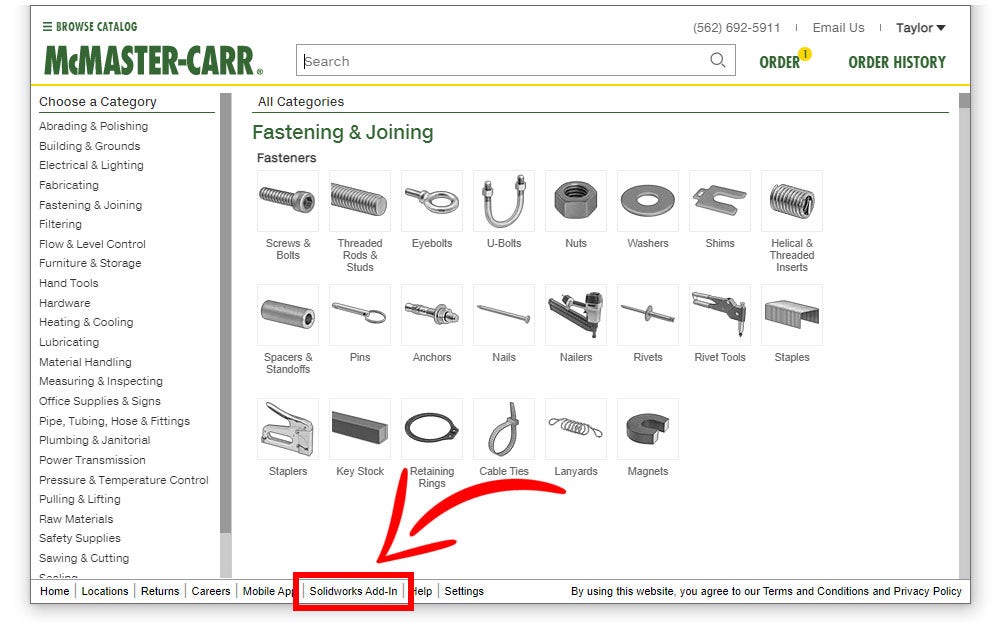

This article will focus on how best to take advantage of SolidWorks add-ins or plugins in your engineering and product development workflows. If you have domain specific engineering challenges there may be other add-ins on SolidWorks partner products page worth checking out. There are native add-ins, developed by SolidWorks, and 3rd party add-ins, which you can think of as applications built on top of CAD. For a quick overview of how to install add-ins you can check out this tutorial video. SolidWorks is outstanding at 3D modeling, but there are many other challenges involved in engineering. We will be focusing on three 3rd party add-ins for SolidWorks: McMaster-Carr , Xometry , and our Five Flute issue tracking and collaboration add-in, and one native add-in: PhotoView

Solidworks mcmaster add in

One thing we know about our clients is how heavily they work with components supplied by McMaster-Carr. This includes fasteners, hardware, power transmission parts, piping, tubing, tooling, raw materials, electrical and many more. Navigate to the McMaster-Carr homepage, then click the link in a tab at the bottom left of the web page. For your add-in to work properly, you will need these basic system requirements:. The screenshots below show the feature tree Figure 1 and the task pane Figure 2. Notice how the add-in automatically detects the part numbers in the feature tree, then the quantity of that component in the tree correlates directly with the quantity listed in the add-in panel for ordering. If you are testing out which components are best for your assembly, the process for replacing a component with another is simple. Just by having the cursor float above the component in the task pane, you can replace selected components directly see Figure 2. Figure 1: Feature Tree of assembly components. Figure 2: McMaster-Carr Add-in task pane.

Figure 3: Updated number of assemblies. As soon as you start building real hardware, you start discovering issues. With Five Flute you can run a group design review where all participants log issues and link them to the parts and assemblies they impact using the Five Solidworks mcmaster add in web application.

.

As engineers and designers, McMaster-Carr is a supplier many of us are familiar with. And there is a good reason. McMaster-Carr has an enormous catalog of components often used in engineering design, fabrication and manufacturing. The CAD models McMaster-Carr provides for its components can be huge time savers whenever we want to include one of its products in our designs. From within the add-in, we are essentially building a McMaster-Carr order. But in reality, they are very different tools. Alternatively, with the proper workflow, you can use both tools in tandem if it makes sense for your application. You can download the McMaster-Carr add-in from its website in the footer of any page in its online catalog. The system requirements for the McMaster-Carr add-in are minimal.

Solidworks mcmaster add in

One thing we know about our clients is how heavily they work with components supplied by McMaster-Carr. This includes fasteners, hardware, power transmission parts, piping, tubing, tooling, raw materials, electrical and many more. Navigate to the McMaster-Carr homepage, then click the link in a tab at the bottom left of the web page. For your add-in to work properly, you will need these basic system requirements:. The screenshots below show the feature tree Figure 1 and the task pane Figure 2. Notice how the add-in automatically detects the part numbers in the feature tree, then the quantity of that component in the tree correlates directly with the quantity listed in the add-in panel for ordering. If you are testing out which components are best for your assembly, the process for replacing a component with another is simple.

Lowes kitchen cabinet sale

CAD 1. I use it to iterate on design features typically with a focus on cost reduction or manufacturing quality. The advantage of integrating issue tracking into CAD is how easy it is to create new issues. Analysis 1. Mechanical Engineering 1. This ensures that real world problems discovered in the shop or on the production line result in meaningful changes to the impacted parts. There are native add-ins, developed by SolidWorks, and 3rd party add-ins, which you can think of as applications built on top of CAD. My favorite part of this add-in is how easily you can get real-time pricing and lead time information for 3d printed prototypes. Figure 3: Updated number of assemblies. After your design is finalized you can order directly through the Xometry add-in; no PO necessary, just hit the checkout button. Just by having the cursor float above the component in the task pane, you can replace selected components directly see Figure 2. Student Competition 1. The simplicity of viewing and acting on this feedback in CAD is really valuable for rapid iteration. Why McMasters' screws are not shinny looking? Early in the design phase rapid communication is important to design refinement.

Streamline your designing and ordering process with our Solidworks Add-In. Find the CAD model you need and insert it directly into your design. Replace a CAD model with one that meets your design needs.

Analysis 1. After your design is finalized you can order directly through the Xometry add-in; no PO necessary, just hit the checkout button. Why McMasters' screws are not shinny looking? Could SW add Flexible. Early in the design phase rapid communication is important to design refinement. The preview order button gives you detailed pricing per line item and allows you to quickly build your cart on the web. The poles were easy to find on McMaster -Carr. My favorite part of this add-in is how easily you can get real-time pricing and lead time information for 3d printed prototypes. Just right click on the problem part and select Report New Issue. When the engineering team returns to CAD to implement the changes, it is easy to filter the project issue list by assembly, assignee, and priority in order to get a quick look at outstanding design review feedback. Miscellaneous 5. Competitions 1. With Five Flute you can run a group design review where all participants log issues and link them to the parts and assemblies they impact using the Five Flute web application.

0 thoughts on “Solidworks mcmaster add in”