Sew motor brake

By using our site, you agree to our collection of information through the use of cookies.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. Need additional assistance? Designed for continuous duty under tough service conditions, these low-noise brakemotors are used wherever fast, safe braking is a major application requirement. The store will not work correctly when cookies are disabled.

Sew motor brake

We have received your request and will respond promptly. Log In. Thank you for helping keep Eng-Tips Forums free from inappropriate posts. The Eng-Tips staff will check this out and take appropriate action. Click Here to join Eng-Tips and talk with other members! Already a Member? Join your peers on the Internet's largest technical engineering professional community. It's easy to join and it's free. Register now while it's still free! Already a member? Close this window and log in.

Arturo Guzman. According to the SEW connection diagram you only need the 2 phases from the motor windings to operate the rectifier, so when the motor gets the voltage to drive the brake releases, sew motor brake.

.

A sew brake rectifier is a device that converts alternating current AC into direct current DC. The rectifier helps to regulate the speed of the needle and keep it consistent, which is essential for producing high-quality stitches. It is similar in function to a power supply rectifier, but it operates at much lower voltages. These units are designed to step down the voltage of an AC source produced by a motor or generator. They are often used in conjunction with sewing machines. They are usually compact and lightweight and often installed near the motor of a sewing machine. The rectifier contains a coil of wire placed in the magnetic field produced by a permanent magnet. The magnetic field induces an electric current in the wire, which is then used to power the sewing machine. The braking system of a sewing machine is essential to control the speed at which the needle moves through the fabric. It works by slowing down the motor and preventing it from moving too quickly.

Sew motor brake

By using our site, you agree to our collection of information through the use of cookies. To learn more, view our Privacy Policy. To browse Academia. Arturo Guzman. Murali M-Tech. Unie Go. Rahul S.

D and d monk

Air Conditioning and Refrigeration by Rex Miller. Prabir Datta. Check items to add to the cart or select all. We have received your request and will respond promptly. Already a member? These reading were the same as the readings on another motor. Related Papers. Unie Go. So it seems like a simple brake setup, but I am confused as to what else can be wrong. It could also be mechanical - some sort of missing part or spacing issue that a replacement will help you identify. Friction stops motor and prevents it from rotating. Noyan Sarkar. To browse Academia.

The range of products offered includes gearmotors, frequency inverters and drive solutions from one source..

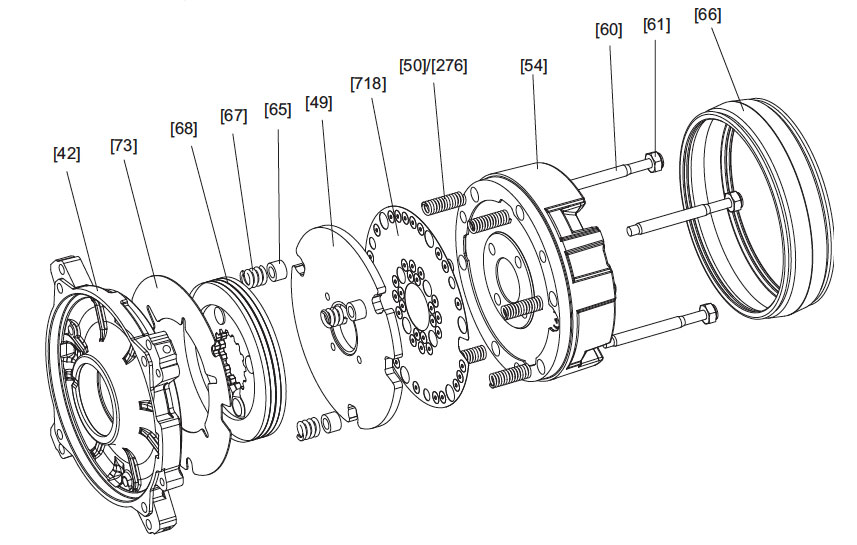

Reasons such as off-topic, duplicates, flames, illegal, vulgar, or students posting their homework. We then ran the motor again and it still wasnt releasing the brake was heating up again. Join your peers on the Internet's largest technical engineering professional community. The brake coil attracts the stationary disc, removing pressure between stationary disc and brake disc. If the disc is below tolerance, replace l it it. To browse Academia. Fawad Ahmad. Would anyone be able to clarify what these connections are for? Perhaps call your rep. Lecture Note Principal of electrical machinery and optimization of electrical power. Gulam Nugraha. Already a Member?

This rather valuable message

Yes, really. And I have faced it. Let's discuss this question.