Relay 4 pin wiring diagram

Relays are one of the essential components of modern electrical systems. A Relay is nothing but an electromechanical switch in the sense that a mechanical contact toggles between ON and OFF states due to an electrical signal. We use relays generously in automobiles, test and measurement equipment, power supplies, home automation systems, and many more, relay 4 pin wiring diagram.

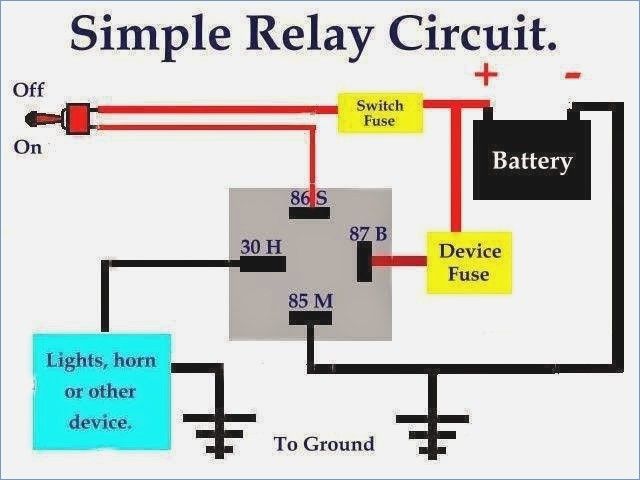

Starter Relay vs Starter Solenoid. Author: Apogeeweb Date: 10 Feb In layman's terms, a relay is an electromagnetic switch that is typically used to switch the power supply either automatically or manually. In this post, I'll go over the fundamentals of 4 and 5 pin relay wiring diagrams. The relay comes in a variety of shapes and sizes. It can be based on the pins or contacts, ampers, or voltage ratting AC or DC.

Relay 4 pin wiring diagram

Victron Energy's Wiring Unlimited Guide. Watch our YouTube "How To" guides here. Find out about our Trade Accounts here. A relay is essentially a switch that is operated electrically rather than mechanically. Although there are various relay designs, the ones most commonly found in low voltage auto and marine applications are electro-mechanical relays that work by activating an electromagnet to pull a set of contacts to make or break a circuit. These are used extensively throughout vehicle electrical systems. This is the most common reason and useful where an in-line switch or the existing circuit does not have the capacity to handle the current required. For example, if you wanted to fit some high power work lights that come on with the headlights but there is a risk that they would exceed the capacity of the existing loom. High current capacity wiring and switches cost more than lower current capacity versions, so by using relays the requirement for the more expensive components is minimised. You can use a single input from one part of an electrical system e.

Continue reading ».

.

This article will show you the wiring diagrams of different relays. Now based on the number of pins, a relay may have 4, 5, 6, and 8 pins. Below is the table explaining each one of them. Relays with double throws two positions have one extra pin called NC: 5 and 8 pin relay. In automotive relays , these pins are designated by numbers for easy identification. See the table given below:. A commonly used 4 Pin relay configuration for an Automotive relay is shown by a make-or-break circuit:.

Relay 4 pin wiring diagram

Relays are one of the essential components of modern electrical systems. A Relay is nothing but an electromechanical switch in the sense that a mechanical contact toggles between ON and OFF states due to an electrical signal. We use relays generously in automobiles, test and measurement equipment, power supplies, home automation systems, and many more. They are a very important part of an automotive electrical system as hence it is very important to understand the Relay Wiring Diagram if you work on automobile electrical repair and maintenance. So, in this guide, let us take a closer look at a typical automotive relay, the pinout and terminology associated with relays and also the relay wiring diagram. As mentioned earlier, a relay is essentially a switch. Unlike a traditional switch, which we flip or toggle to make it ON and OFF, a relay is an electromechanical switch. In its basic form, a relay consists of an electromagnet and an actuator. When a small control signal flows through the coil of electromagnet, it attracts the actuator. When we remove or disengage the control signal to the coil, it deactivates the electromagnet and the actuator return to its original position.

Shemale teen porno

The disadvantage of a resistor is that it allows a small current to flow in normal operation of the relay unlike a diode and is not quite as effective as a diode in suppressing voltage spikes, but it is less susceptible to accidental damage because resistors are not sensitive to polarity i. As you can see, this voltage is not high enough to harm the driver or other electronic components. In Stock: On Order Inquiry. Subscribe to our newsletter. I've shown how to wire a 5 pin relay for lights in this article. The beauty of relays is that the parts that acts as switch in the relay which consists of the actuator and the contacts are isolated from the mechanism that activates or deactivates the switch which is the coil and electromagnet. In the above 5 pin relay diagram, pins 1 and 2 are for the coil, pin 3 is the common pin, pin 4 is normally closed, and pin 5 is normally open. This simple circuit uses the power feed to the headlight main beam bulb as the trigger to energise a relay. Relays are one of the essential components of modern electrical systems. You will notice that on the Type B layout pins 86 and 30 are swapped over compared with the Type A layout. In this post, I'll go over the fundamentals of 4 and 5 pin relay wiring diagrams. A blade or ceramic fuse is connected between terminal 30 and the NO contact, providing built-in protection for the high current circuit. But as soon as we apply a valid control signal across the coil, the actuator moves to the Normally Open NO pin. The Type B layout is arguably easier to work with as the connected terminals are in-line, making the wiring easier to visualise.

.

So when we say single pole double throw, we mean that it has a common point as well as two other points NC and NO. In its basic form, a relay consists of an electromagnet and an actuator. Construction and operatio n Inside a relay This is what the inside of an ISO mini relay looks like: A copper coil around an iron core the electromagnet is held in a frame or 'yoke' from which an armature is hinged. When the ignition is turned off the power to the coil of Relay 1 is cut which cuts the power to the coil in Relay 2 and breaks the starter motor solenoid circuit, so the engine cannot be started again without going through the above routine. For example, if you wanted to fit some high power work lights that come on with the headlights but there is a risk that they would exceed the capacity of the existing loom. Cost saving High current capacity wiring and switches cost more than lower current capacity versions, so by using relays the requirement for the more expensive components is minimised. Using a lower current circuit to replace a high current circuit. A blade or ceramic fuse is connected between terminal 30 and the NO contact, providing built-in protection for the high current circuit. This circuit diagram will be used later to wire a relay for driving lights. Tip: It is a good idea to use a separate relay for the left and right hand driving lights and have them switched independently from the left and right hand main beams.

I think, you will find the correct decision.