Ratrig extruder

JavaScript seems ratrig extruder be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

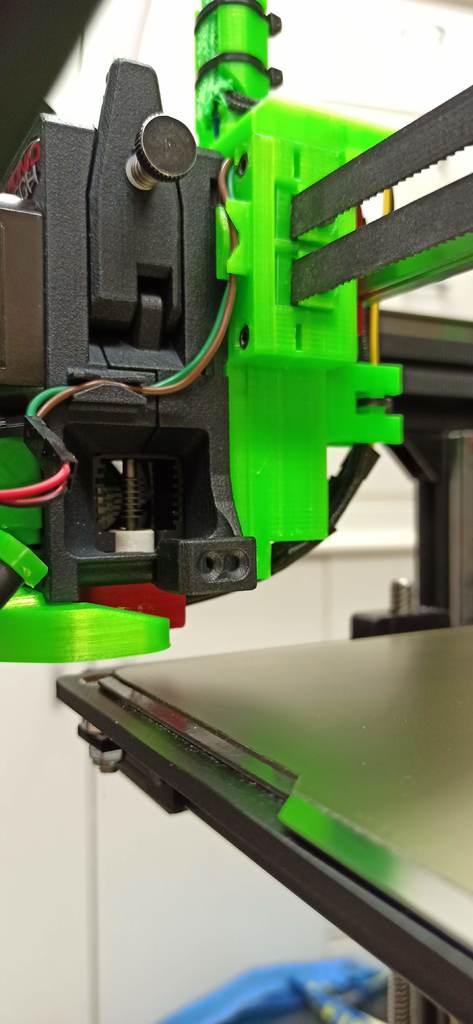

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. Creating an account has many benefits: check out faster, keep more than one address, track orders and more. The new version of the LGX Lite Extruder has a new and improved housing and build allowing for: Improved build quality with a sturdier 2 parts housing design and precise stepper motor centering Tighter tolerances Extra mounting point Increased resistance to heat Micro form factor, featherweight and small footprint Direct replacement for the previous version Enhanced filament grip Includes full size LGX Large Gears and maintenance windows Filament pre-tension lever for repeated results, with 3 presets open; rigid; flexible. It has a new and improved housing, and build quality, with a sturdier 2 parts housing design and precise stepper motor centering allowing for tighter tolerances and enhanced filament grip. While still being a direct replacement for the previous version. To lower the ecological impact Bondtech is reducing the use of chemical dyes.

Ratrig extruder

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. Creating an account has many benefits: check out faster, keep more than one address, track orders and more. The store will not work correctly in the case when cookies are disabled. This is the International Store. My Account Registered Customers. If you have an account, sign in with your email address. Sign In. Forgot Your Password? New Customers. Create an Account. Remove This Item. Clear All. Add to Cart Add to Cart.

Step 6 Attach the front and back to the top.

Hi there, I have been using klipper for over a year now and hardly had any problems, at least nothing I could not solve. Now I ran into a wall and I get the same problem over and over. I have a custom cube mixture of Hypercube and ratrig and I am using superslicer with the ratrig-profile. Today my print stopped with an error messag after the it had drawn the circle around the printing area. I restarted, re-scliced several times but it continued. It always happend when printing the actual object started.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. Creating an account has many benefits: check out faster, keep more than one address, track orders and more. Lead Time and Shipping information. Learn everything about the V-Core 3 on the dedicated project page: v-core. If you want some choice on the components that go into your machine, you should probably be looking at the V-Core 3 Configurable Kit. This "Standard kit" is meant for users who are unsure about which configuration options to choose, and are above all else interested in acquiring a kit as complete as possible, including all necessary electronics, and with proper documentation to guide them from beginning to end. If you're not feeling particularly adventurous, this is the V-Core 3 "walled garden". For full transparency, this is our favourite machine configuration and the one we use on our own print farm. Make sure you read the longer description below, so you understand exactly what you're buying!

Ratrig extruder

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. Creating an account has many benefits: check out faster, keep more than one address, track orders and more. You can read more about the new features by going to Bondtech website. Extruder and Stepper Motor go together Preferably, you should always use the extruder attached to the stepper motor when you mount it on a printer. If you need to put a plate in between the stepper motor and the extruder please notice that you need longer screws, and the max supported thickness is 3mm. This image below shows what screws are used on the LGX, and the red ones are used to attach the stepper motor and extruder:.

Right foor creep

I could go up to 50 but if it is a sefty feature I do not want to. Sineos August 24, , pm 4. As far as I understood, this is a safety feature and one should not raise the value. There you have to squeeze in the PTFE tube. This guide will show you the principles and basic EVA modules, so you can easily figure out how to assemble other variants if needed. Step 9 Assemble the E3D V6 face. I chose the LGX-Lite and Mosquito Magnum setup which is similar to the Mosquito setup but hard a hard time conversing the illustrated example to my chosen setup. This step assumes a 40mm x 10mm fan for a fan you need screws that are 10mm longer. Step 12 Assemble the extruder. The store will not work correctly in the case when cookies are disabled. Move exceeds maximum extrusion 0. New Customers. Adding it afterwards starting at the extruder introduces the risk of a clogging gap on the Mosquito side.

The new Rat Rig Toolheads are the result of painstaking testing and design iteration to achieve optimal printing performance. With a rigid, light and compact metal body, they use only a few printed parts which are supplied in ABS, to withstand the high temperatures of an enclosed printer. STLs for optional toolboard mounts are also available.

The belt does not have to end flush with the groove, it can go over it. Step 17 Tension the belts. Would you like to save this store view for the next visit? Step 12 Assemble the extruder. This step assumes a 40mm x 10mm fan for a fan you need screws that are 10mm longer. Clear All. This guide will show you the principles and basic EVA modules, so you can easily figure out how to assemble other variants if needed. Step 1 Assemble the top part. For the best experience on our site, be sure to turn on Javascript in your browser. This image below shows what screws are used on the LGX, and the red ones are used to attach the stepper motor and extruder: To use a plate in between the stepper motor and the extruder, you need to replace the stock M3x27 low head screws with the 3 M3x30 low head screws we send in the accessories bag, which are compatible with printer plates of thicknesses between 2 and 3mm. I set the slicer to relative mode and that seemed to do the trick, the printer is still running.

0 thoughts on “Ratrig extruder”