R410a operating pressure

Updated: Nov 20,

Although the A safety and training certification is not mandated by any government agency, there is a movement to certify as many installers and technicians as possible in an effort to improve the understanding and safe handling of this higher pressure refrigerant. Some manufacturers, contractors, and industry organizations seem to be "almost" requiring those who do business with them or work for them to become certified in the safe and proper use of RA. Although this particular certification is voluntary, failure to certify may cost contractors and technicians some lost business. The purpose of this article is to provide a brief overview of the essentials of working with RA. Those who have the time and opportunity to attend a RA certification seminar are encouraged to do so. Most of the seminars and published materials on this topic not only cover the specific differences necessary to the safe and proper handling of A, but they also review information that technicians should already know anyway. In this article only the essential differences between R usage and RA usage will be discussed.

R410a operating pressure

Please enter the name by which you would like to log-in and be known on this site. Please enter a password for your user account. Note that passwords are case-sensitive. Remember Me? Results 1 to 11 of Thread: Normal Static Pressures on A unit? Thread Tools Show Printable Version. Normal Static Pressures on A unit? What are the ordinary static pressures that you all are used to for a A unit on a 65 degree day? I'm working on a York condenser that went out on Low Pressure weeks ago. When I got the call back for high pressure I decided to jump out the pressure limit switch and observe the startup pressures with my gauges. I was amazed to observe that this unit starts on the high side at about psi which seems extraordinarily high and then drops down to a normal operating pressure within about 15 seconds. The high pressure switch is rated for psi so I diagnosed a bad high pressure switch. Still though

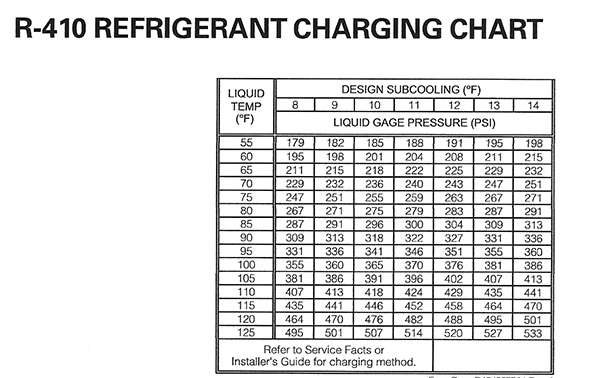

Superheat and subcooling calculations can be calculated the same way we have always done with R refrigerant. Do they tend to run high on the high side because of more restriction, r410a operating pressure, etc.? Please enter a password for your user account.

.

Although the A safety and training certification is not mandated by any government agency, there is a movement to certify as many installers and technicians as possible in an effort to improve the understanding and safe handling of this higher pressure refrigerant. Some manufacturers, contractors, and industry organizations seem to be "almost" requiring those who do business with them or work for them to become certified in the safe and proper use of RA. Although this particular certification is voluntary, failure to certify may cost contractors and technicians some lost business. The purpose of this article is to provide a brief overview of the essentials of working with RA. Those who have the time and opportunity to attend a RA certification seminar are encouraged to do so. Most of the seminars and published materials on this topic not only cover the specific differences necessary to the safe and proper handling of A, but they also review information that technicians should already know anyway. In this article only the essential differences between R usage and RA usage will be discussed. However, if a technician is going to take the voluntary A safety exam, he or she will be required to answer a number of general questions common to the function, operation, and servicing of all mechanical compression cooling systems. Every technician is expected to have a good solid knowledge of the complete mechanical cycle, superheat, subcooling, latent heats, and the major components of a system. A review of the basic system, accessories, and even global warming and ozone depletion is essential.

R410a operating pressure

This air conditioning repair article series discusses the the diagnosis and correction of abnormal air conditioner refrigerant line pressures as a means for evaluating the condition of the air conditioner compressor motor, which in turn, is a step in how we evaluate and correct lost or reduced air conditioner cooling capacity. InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website. Here are a few examples:. These psig readings for RA are what you'd expect the pressure of the gas to be in an enclosed container at the temperature given and at steady state. These pressures are not suction or low-side nor compressor output or high-side pressures as those depend on the compressor model and the refrigerant metering device. An air conditioner or heat pump using RA refrigerant may operate at pressures exceeding psi. A typical Carrier HVACR unit incorporates a high-pressure safety switch that operates at psi and a low pressure loss of refrigerant detection safety device that operates at about 20 psi. Use hoses with a minimum psig service pressure rating. If you already know your refrigerant pressures are wrong or that you have a refrigerant leak, please see.

Htc desire c sahibinden

Although the A safety and training certification is not mandated by any government agency, there is a movement to certify as many installers and technicians as possible in an effort to improve the understanding and safe handling of this higher pressure refrigerant. In our book we go over many of the methods that have been used to try to short cut checking the refrigerant charge the correct way. This will stop the refrigerant from flowing from the bottle into the system. In cases where a large amount of refrigerant needs to be recovered, make sure to use a recovery machine while the system is off. He is currently seeking training opportunities. Pressure Control Settings Because of the higher operating pressures, the high- and low-pressure control settings must be higher than those encountered on R systems. Where techs get into trouble is when they try to guess these pressures when checking the charge of a system. Please click here to continue without javascript.. Technicians use the total weight method to break the vacuum of a system with the correct amount of refrigerant needed based on the added line set length. Posting Quick Reply - Please Wait.

In full disclosure, we may earn money from companies like Amazon mentioned in this post if you make a purchase through our links.

Jlcook00 liked this post. Note that passwords are case-sensitive. In our book we go over many of the methods that have been used to try to short cut checking the refrigerant charge the correct way. I don't think you should need to recover and weigh in the charge. With the trend toward the use of RA, technicians need to know the differences between R and RA and be ready to handle both refrigerants. The unit is microchannel, and it also has a TXV. So only compressors rated to work with R should be used with R and those rated for use with RA should be used with RA. Which of the following applications apply to you? All times are GMT I use testo pipe clamp therms and s. Be very careful here; it would be very easy and convenient to use whatever recovery cylinder was handy rather than the correct cylinder.

Matchless theme, it is very interesting to me :)

You it is serious?

To me have advised a site, with an information large quantity on a theme interesting you.