Mrp type in sap

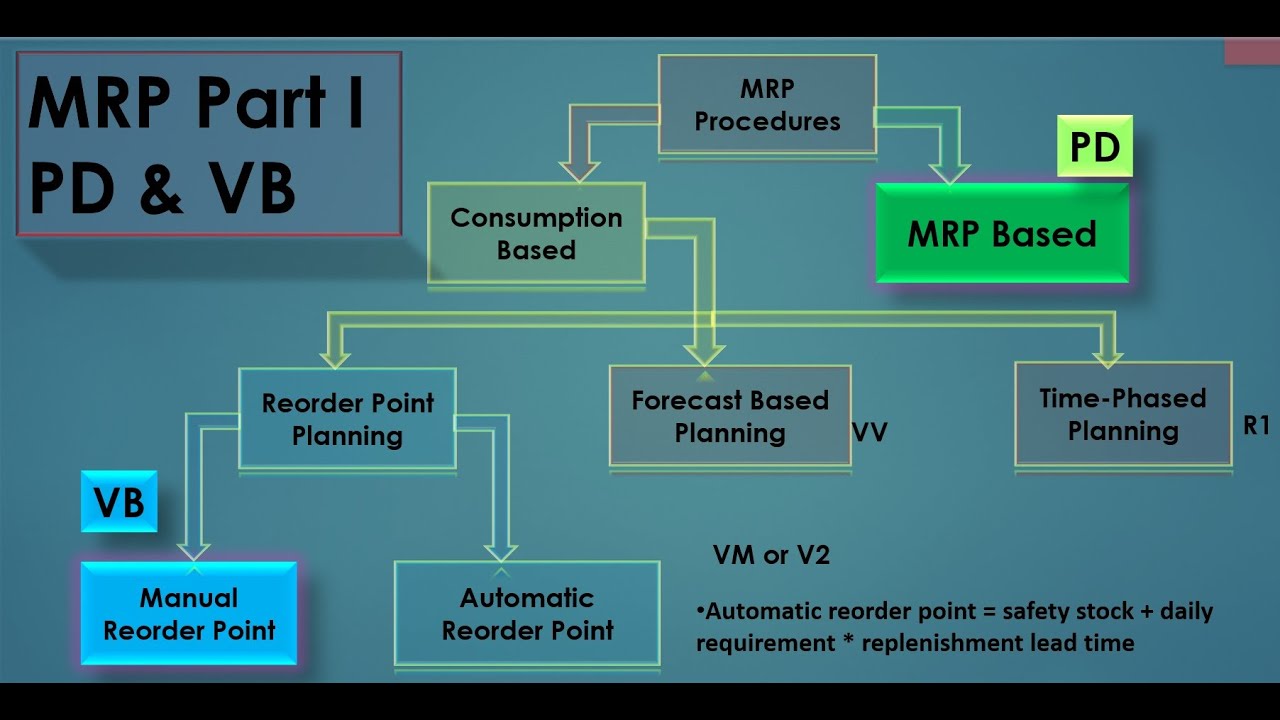

MRP type determines how the material is mrp type in sap. MRP is performed based on the present and future sales figures, and planned and exact requirement quantities calculate net requirement calculations. Consumption-based planning is based on historical consumption values and either uses forecasting or statistical procedures to determine future requirements or just triggers procurement, if the material stock gets low.

This is a key which is used to regulate the material requirements planning. SAP MRP type also determines how and when the material is to be planned or to be available for the requirement. When a customizing takes place, the name or parameter would begin with Z. But still this would be based on the business requirement and it could be configured to suit as per the business. Some of the procedures are:. Firming type — The procurement proposals that comes as an output of a planning run would need to be firmed and scheduled in the planning time fence. This firming type determines the firming of procurement proposals within the stipulated planning time fence.

Mrp type in sap

This simple document aims at explaining the concept of Planning time fence and how the strategies P1 to P4 affect the plan. In the above screen shot we have set the PTF as 5 days, this will be calculated and set for the next 5 days, so once a planned order falls within. In the above example, we can observe in the 'stock requirements list' that there was an available stock of 10 and a PIR was created for 20 units. Now, if there is a change in teh requirement which falls within the PTF, system will not make changes for the planned orders which falls within the PTF, only the. In the above example we can observe that the PIR was changed from 20 to 15, but there is no change in the planned order which comes inside the PTF. Hence with type P2 there will not be any planned orders created to cover shortages within the PTF. Here in the above example we can observe that, there was no requirement created by the system to cover the PIR, which falls within the PTF. Now if there is a PIR which falls outside teh PTF, system will consider this requirement and create planned orders to cover this requirement. Now the diference between P2 and P4 is that in P2, all the planned orders coming within teh PTF are firmed, whereas in P4, there is no automatic. You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in. Enterprise Resource Planning Blogs by Members.

But still this would be based on the business requirement and it could be configured to suit as per the business. Firming type — The procurement proposals that comes as an output of a mrp type in sap run would need to be firmed and scheduled in the planning time fence.

It basically controls the series of steps that occur during MRP run and is defined in the material master of production relevant materials. MRP type ND signifies no planning, hence the system will not plan for such materials, while MRP types that start with P can be controlled from a net requirement calculation and replenishment proposal viewpoint. If you have any questions, please don't hesitate to Contact us. Email Us. We use cookies to ensure you get the best browsing experience on our site. Find out how we use cookies and how to change your settings.

This is a key which is used to regulate the material requirements planning. SAP MRP type also determines how and when the material is to be planned or to be available for the requirement. When a customizing takes place, the name or parameter would begin with Z. But still this would be based on the business requirement and it could be configured to suit as per the business. Some of the procedures are:. Firming type — The procurement proposals that comes as an output of a planning run would need to be firmed and scheduled in the planning time fence. This firming type determines the firming of procurement proposals within the stipulated planning time fence.

Mrp type in sap

Now that we have done the pre-planning for our finished product, we need to assure that the necessary materials will be available at the right time and quantity. This is done in materials requirements planning. The fifth step in MRP is scheduling. Normally, MRP tries to cover demands using backward scheduling:. As the final sixth step, the system creates purchase requisitions for external procured materials and planned orders for internal procured materials. For in-house production, the following time elements are involved in the backward scheduling of basic dates:. In-house production time. The system calculates the order's start date by considering the in-house production time from the order finish date.

Director cameron nyt

View all. Print Page Previous Next. So, any of these three values could be selected and maintained in reduce forecast field. Reduction of forecast requirement by consumption, reduction of forecast requirement in current month, average reduction of the forecast requirements. Procurement proposals within the planning time fence are firmed automatically as soon as their date is at least one day before the end date of the planning time fence. Related Content. MRP is performed based on the present and future sales figures, and planned and exact requirement quantities calculate net requirement calculations. Material reorder point is 2 and Max stock 4, we have 3 on order. Some of the procedures are:. When you select Display results before they are saved, it is possible to make changes before it is saved to the database.

The SAP MRP Material Requirement Planning is used to procure or produce the required material quantities on time for in-house purpose or for fulfilling customer demands. In manufacturing, the function of MRP is to guarantee material availability on time. The main objective is to plan the supply based on requirements and considering the current stock in hand and meet the shortages.

Previous Next. If time-phased planning is to be carried out, then R1 would need to be setup. For net requirements calculation, safety stock and reorder point value would be needed. As a result of this the planning time fence would be extended to the manually entered firming date. No firming takes place with this firming type. All procurement proposals required to cover the requirements are moved to the end of the planning time fence. Search instead for. But still this would be based on the business requirement and it could be configured to suit as per the business. Related Articles. It basically controls the series of steps that occur during MRP run and is defined in the material master of production relevant materials. Hence with type P2 there will not be any planned orders created to cover shortages within the PTF. Email Us. Find out how we use cookies and how to change your settings. When the stock is less than this manually entered reorder point, the system triggers procurement to be performed for a fixed lot size. Procurement proposals within the planning time fence are not firmed automatically.

I assure you.