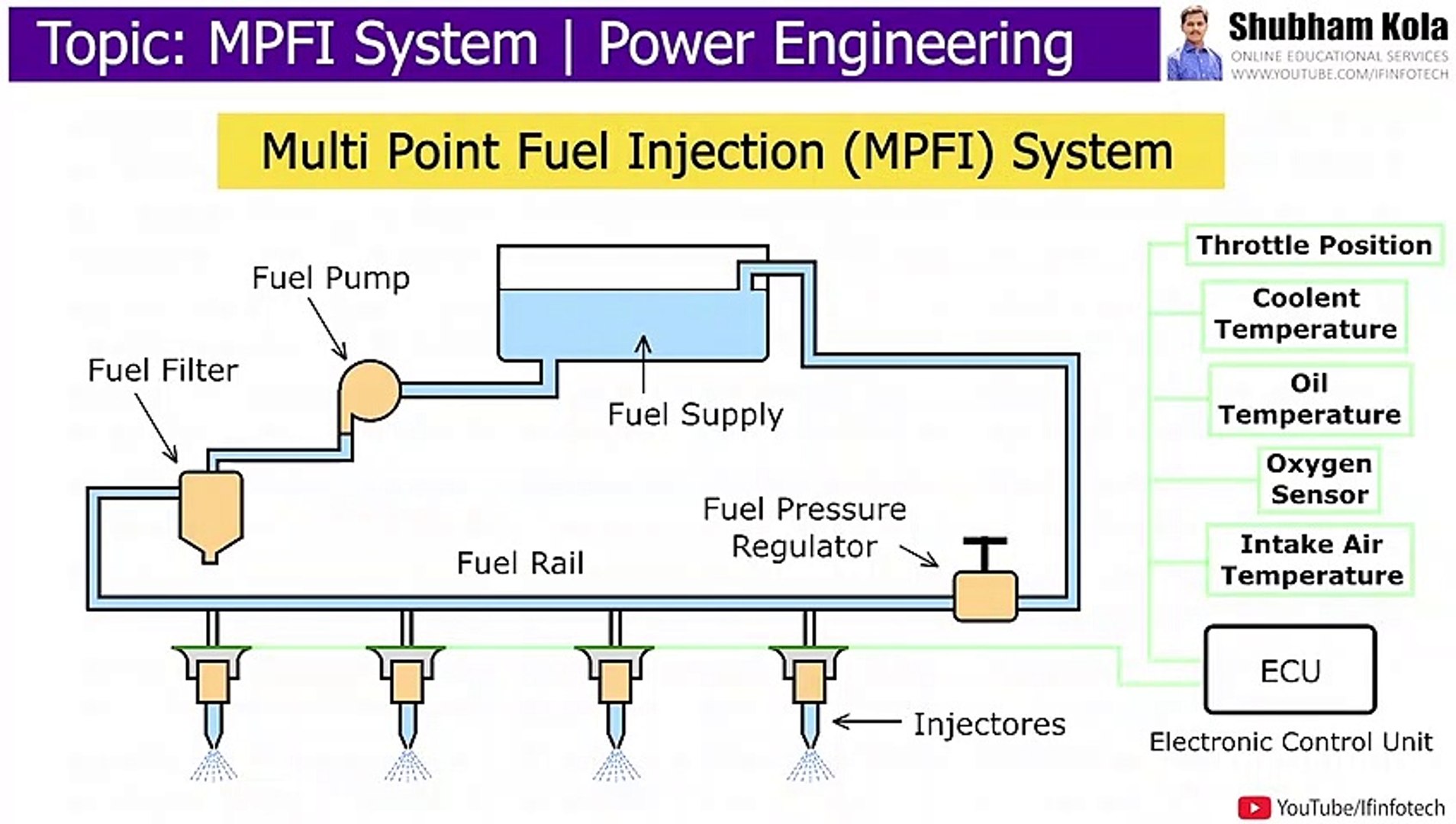

Mpfi system diagram

What is multi point fuel injection MPFI system? The MPFI is a system or method of injecting fuel into internal combustion engine through multi ports situated on intake valve of each cylinder. It delivers an exact quantity of fuel in each cylinder at the mpfi system diagram time. In the batched MPFI system fuel is injected to the groups or batches of the cylinders without bringing their intake stroke together.

Despite the rapid development in carburetors which are cheap and efficient, the automobile industry prefers to use a gasoline injection system in spark ignition S I Engines. Then, there must be some advantages of the gasoline injection system over the carburetor system which we are going to see it at the end of this article. In this article, we are going to learn about components, use, and working of multi point fuel injection system. Read about Working of Simple Carburetor. Nowadays, it is widely used in light commercial vehicles. MPFI system is the most advanced gasoline injection system the automobile industry currently has.

Mpfi system diagram

In trying to keep up with emissions and fuel efficiency laws, the fuel system used in modern cars has changed a lot over the years. The Subaru Justy was the last car sold in the United States to have a carburetor; the following model year, the Justy had fuel injection. But fuel injection has been around since the s, and electronic fuel injection was used widely on European cars starting around Now, all cars sold in the United States have fuel injection systems. In this article, we'll learn how the fuel gets into the cylinder of the engine, and what terms like "multi-port fuel injection" and "throttle body fuel injection" mean. The Fall of the Carburetor For most of the existence of the internal combustion engine, the carburetor has been the device that supplied fuel to the engine. On many other machines, such as lawnmowers and chainsaws, it still is. But as the automobile evolved, the carburetor got more and more complicated trying to handle all of the operating requirements. For instance, to handle some of these tasks, carburetors had five different circuits: Main circuit - Provides just enough fuel for fuel-efficient cruising Idle circuit - Provides just enough fuel to keep the engine idling Accelerator pump - Provides an extra burst of fuel when the accelerator pedal is first depressed, reducing hesitation before the engine speeds up Power enrichment circuit - Provides extra fuel when the car is going up a hill or towing a trailer Choke - Provides extra fuel when the engine is cold so that it will start In order to meet stricter emissions requirements, catalytic converters were introduced. Very careful control of the air-to-fuel ratio was required for the catalytic converter to be effective. Oxygen sensors monitor the amount of oxygen in the exhaust, and the engine control unit ECU uses this information to adjust the air-to-fuel ratio in real-time. This is called closed loop control -- it was not feasible to achieve this control with carburetors. There was a brief period of electrically controlled carburetors before fuel injection systems took over, but these electrical carbs were even more complicated than the purely mechanical ones. At first, carburetors were replaced with throttle body fuel injection systems also known as single point or central fuel injection systems that incorporated electrically controlled fuel- injector valves into the throttle body. These were almost a bolt-in replacement for the carburetor, so the automakers didn't have to make any drastic changes to their engine designs.

Wrapped around it is the secondary coil.

Up until the mids, the majority of cars had carburetors; however, today, every car on the market, regardless of price, has a Multi-Point Fuel Injection System MPFI. The first mass-market MPFI automobiles were introduced here in the late s, and as time went on, as emission standards tightened and automakers focused more on boosting vehicle efficiency, every car on the market began to include this technology. After the various articles published on this site on a fuel injection system in internal combustion engines, here we are on the multi-point injection types. The multi-point injection is a system or technique in which fuel is introduced into the cylinder of an internal combustion engine. Just as earlier mentioned, the MPFI is a system of injecting fuel into an internal combustion engine through multiple ports situated on the intake valve of each cylinder. Conventionally, petrol or gasoline engines are also called spark ignition SI engines.

Up until the mids, the majority of cars had carburetors; however, today, every car on the market, regardless of price, has a Multi-Point Fuel Injection System MPFI. The first mass-market MPFI automobiles were introduced here in the late s, and as time went on, as emission standards tightened and automakers focused more on boosting vehicle efficiency, every car on the market began to include this technology. After the various articles published on this site on a fuel injection system in internal combustion engines, here we are on the multi-point injection types. The multi-point injection is a system or technique in which fuel is introduced into the cylinder of an internal combustion engine. Just as earlier mentioned, the MPFI is a system of injecting fuel into an internal combustion engine through multiple ports situated on the intake valve of each cylinder. Conventionally, petrol or gasoline engines are also called spark ignition SI engines.

Mpfi system diagram

Despite the rapid development in carburetors which are cheap and efficient, the automobile industry prefers to use a gasoline injection system in spark ignition S I Engines. Then, there must be some advantages of the gasoline injection system over the carburetor system which we are going to see it at the end of this article. In this article, we are going to learn about components, use, and working of multi point fuel injection system. Read about Working of Simple Carburetor. Nowadays, it is widely used in light commercial vehicles.

Home alone 123movies

The spark plug must have an insulated passageway for this high voltage to travel down to the electrode, where it can jump the gap and, from there, be conducted into the engine block and grounded. Table of Contents. Fail- Safe Function When a trouble has occurred in such area of electronic fuel injection system that includes the following parts and a failure signal is sent to ECM. All of these tasks require digital outputs. In this picture, you can see three of the injectors. This field induces a current in the coils -- a very high-voltage current up to , volts because of the number of coils in the secondary winding. A fuel injection system mixes fuel and air and injects the mixture into the cylinders of an internal combustion engine. This gives the ECU total control over spark timing. The tiny amount of power that the processor can output energizes the transistor in the digital output, allowing it to supply a much larger amount of power to the cooling fan relay, which in turn provides a still larger amount of power to the cooling fan. All Popular Cars. These systems have a fuel injector for each cylinder, usually located so that they spray right at the intake valve. MPFI includes a fuel pressure regulator, fuel injectors, cylinders, pressure spring and a control diaphragm. Flag for inappropriate content. If the spark plug gets too hot, it could ignite the fuel before the spark fires; so it is important to stick with the right type of plug for your car. In the simultaneous system, fuel is inserted to all cylinders at the same time, while the sequential system injection is timed to overlap with intake stroke of each cylinder.

In the realm of modern automotive technology, fuel injection systems have revolutionised the way engines operate, leading to increased efficiency, performance, and reduced emissions. This article will provide a deep insight into MPFI, its working principles, benefits, and its impact on the automotive industry.

MSA Website Sldccdddddddddddddddfgew rgawrgkhrawg msaucla. Instead, they use a sensor that tells the engine control unit ECU the exact position of the pistons. Since the processor on the ECU is a digital device, it needs a component that can convert the digital number into an analog voltage. Next we'll go through the components that make the spark. Some cars with high- performance engines naturally generate more heat, so they need colder plugs. However, since its use is primarily for performance engines, fuel efficiency is not a major concern. Jump to Page. Lowering temperatures helps reduce the formation of nitrogen oxides NO x , which are a regulated pollutant. Fuel injector Md Ansari. Types o Sequential multi-point fuel injection systems use timed injections to coincide with the intake stroke of each cylinder. In conclusion, a multi-point fuel injection system is also a method of injecting fuel into internal combustion engines. In trying to keep up with emissions and fuel efficiency laws, the fuel system used in modern cars has changed a lot over the years. Electronic fuel injection system [EFI]. A cam in the center of the distributor pushes a lever connected to one of the points.

You have hit the mark. In it something is also to me your idea is pleasant. I suggest to take out for the general discussion.

In my opinion you are not right. I can prove it. Write to me in PM.

Plausibly.