Magnacut composition

S30V was developed by Crucible and released at the end of As I began to be interested in knives and steel in my teens the magnacut composition of developing a new steel was very interesting to me.

Condition: This alloy been properly annealed and is in the soft condition. You do not have to do any non-standard wasteful processes before heat treating. The steel must be heat treated to get to a hardened state. Follow the heat treat recipe and the steel will harden. The rating scale is , 0 being minimum and being maximum. The ratings are the maximum potential of the alloy.

Magnacut composition

MagnaCut steel was born out of a passion for both steel and knives. It's a steel designed specifically for knives, combining a high degree of toughness and wear resistance in a balance no other stainless steel quite achieves. Montana Knife Company uses MagnaCut steel for many of our blades because of this exceptional balance. In today's blog post, we're going to do something a little different. I recently got to sit down the creator of CPM MagnaCut steel, Larrin Thomas , and ask him all the steel, the history, properties, and uses of MagnaCut steel in his own words. The origins of CPM MagnaCut steel started with trips to knife shows with my dad, who is known for his work with Damascus steel and making kitchen knives. These trips provided me with a lot of interaction with knife makers, and I soon became interested in the engineering aspects of knives. Intrigued, I started studying how steel was made. The interest never waned, eventually leading to a PhD in metallurgical engineering and work as a steel metallurgist. As a hobby, I started writing about knife steel and doing knife steel experiments. My experiments led to a new idea for knife steel.

Either of those are good at high hardness, Rc.

Mouse over element names to get quick help on its effects in the alloy. CPM MagnaCut was designed as a rather wide range use steel, that could cover everything from heavy use blades to high performance, fine edge cutters. All that combined with high stain resistance. Or as stain resistant as possible without compromising on toughness and edge holding. Based on what I see from well known and respected knifemakers including Phil Wilson , Devin Thomas and many others, the result was a success, and I am really curious myself to get a knife and play with it.

Knife Steel. July 19, MagnaCut steel has gained massive recognition in the world of high-performance materials, particularly in the knife-making industry. As an advanced stainless steel alloy, MagnaCut boasts a unique combination of properties. Developed by Larrin Thomas at Knife Steel Nerds , it has quickly become a popular choice for many knife enthusiasts. The well-balanced characteristics of MagnaCut have proven advantageous for various cutting tools. It is considered a must-try for those seeking a high-quality option. The primary makeup of MagnaCut steel includes iron, carbon, chromium, molybdenum, nitrogen, etc. The combination of these elements forms a steel that exhibits high corrosion resistance, exceptional edge retention, and great toughness.

Magnacut composition

Mouse over element names to get quick help on its effects in the alloy. CPM MagnaCut was designed as a rather wide range use steel, that could cover everything from heavy use blades to high performance, fine edge cutters. All that combined with high stain resistance. Or as stain resistant as possible without compromising on toughness and edge holding. Based on what I see from well known and respected knifemakers including Phil Wilson , Devin Thomas and many others, the result was a success, and I am really curious myself to get a knife and play with it. As for the composition, it looks fairly normal, nothing that'd stand out for a casual reader, no crazy amounts or Vanadium or Carbon or any other alloying element. CPM MagnaCut has much more conventional 1. Max working hardness for CPM MagnaCut came out around 65HRC with cryogenic treatment, which is really high even for many carbon steels, and really high for stainless ones.

Mercimek köftesi tarifi 2 kişilik

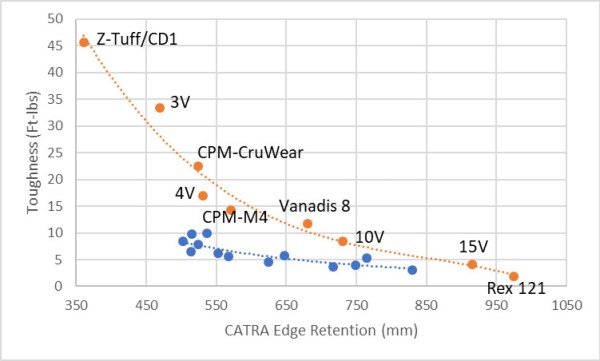

The hardness is somewhat higher if a cryo step is added after the quench. Well done!! I wonder how much percentage of chromium carbide exist in this new steel. Removing chromium carbides in MagnaCut led to an improvement in corrosion resistance that makes sense in retrospect but was a surprise when I first tested it. Fantastic work. I have never heard of an independent metallurgist offering a steel design to a company out of the blue. Would you say this approach of minimising the formation of chromium carbides could open to door for more development in other grades of stainless steel? Barmond has it, though it looks like they are selling shorter lengths. A heat treating company heat treated MagnaCut with half the holding time. The new design eliminating chromium carbides gives MagnaCut a much better edge retention-toughness balance than previous PM stainless steels, and gives performance similar to the best non-stainless PM steels. People sometimes ask for recommendations on Rockwell hardness and edge geometry for MagnaCut knives, but really, it depends on you and how you're going to use your knife. Equalize temperature. This may be helped by the decreasing hold time I recommend at higher temperatures, but either way the grain size is very fine across the recommendations. If someone is also feeling creative about new tool steels, a steel with the highest possible combination of toughness and hardness, would also be very interesting for our production processes — which is shearing relatively hard wire.

S30V was developed by Crucible and released at the end of

The big difference came in the nail chop test where the had significant deformation; a typical resharpening was unable to take the edge back. S30V was developed by Crucible and released at the end of Now to test out a new steel concept you have to make a full heat of several thousand pounds. Thrilled to see Magnacut at distributors again. Instead, simply allow others to praise your significant accomplishment and the sales will follow. All that combined with high stain resistance. I am so glad I am able to learn and research info from metallurgist like yourself Larrin. Kudos for the monumental achievement and wonderful outcome. Cryo if desired. I talked to Crucible metallurgists at every knife show I attended and even called them up frequently with many questions and they always did their best to answer. As a rule, carbon steel knives are a little tougher and easier to sharpen, and MagnaCut knives are a little more wear resistant and corrosion resistant. Some of the marketing around it is somewhat dubious.

It is remarkable, rather amusing phrase

Yes, really. And I have faced it.