M code vmc

Follow along with the video below to m code vmc how to install our site as a web app on your home screen. Note: This feature may not be available in some browsers. This website or its third-party tools process personal data e.

Follow along with the video below to see how to install our site as a web app on your home screen. Note: This feature may not be available in some browsers. This website or its third-party tools process personal data e. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy.

M code vmc

This price includes shipping cost, export and import duties, insurance, and any other expenses incurred during shipping to a location in France agreed with you as a buyer. Sign up now! MyHaas Welcome,! Find Your Distributor. Multi-Axis Solutions. Horizontal Mills. Automation Systems. Spindles Spindles. Tool Changers. The Haas Control.

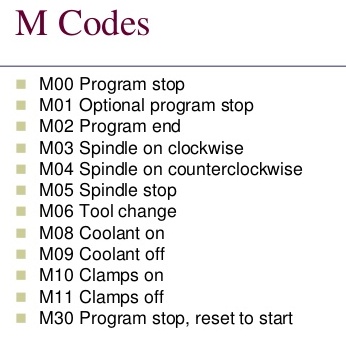

The On-Off-Auto switch is a big hint. Playing with unknown M-codes can be a dangerous thing to do, I didn't know how else to find out. Below you will find a list of common codes many builders use, m code vmc.

Below you will find a list of common codes many builders use. Please remember, all machines may be configured differently and the list below may not match your machine perfectly. If fact, virtually all M-Codes above M79 will vary from builder to builder. Please make sure to contact your machine tool builder to be sure. G00 X……. X axis address Y…..

From the above table, you can easily understand how to give M code input to the Vmc machine for getting Machine movement output. From the above table, we can observe one thing Vmc m codes are used mostly for 5 above purposes :. You can easily read it online or if required you can also Download the vmc machine m code list pdf with just one click. Most CNC and Vmc learners only know about standard M codes which are defined by machine manufacturers. But there is one big magic, we can create Vmc M code user-defined or Custom M codes by making a subprogram for that. Following are some important things of fanuc control to create Custom M codes.

M code vmc

Provide efficient production and faster design to delivery. Produce precision parts that exceed industry standards. Create and test products quickly to bring them to market.

Hustler hollywood richmond va

There may be some confusion regarding the codes for CNC machines since some operators refer to all codes as being G-codes even though they input both G and M codes. Unless you look, ther is no reason to assume that there is no contactor for it. And perhaps is running it manually continually now. The key to the success of CNC manufacturing is the initial programming. The types of applications performed by CNC machines include bushings, collars, fasteners, fittings, inserts, machined components, machined washers, pins, nuts, spacers, spindles, standoffs, drive shafts, and splined shafts to name a few. Click to expand This price includes shipping cost, export and import duties, insurance, and any other expenses incurred during shipping to a location in France agreed with you as a buyer. Using an M code in a program is how I use mine.. The factory documentation listed a different M-code than the one that actually worked. As with any computer, CNC machines have a controller for data input. Alarm if Skip Signal Not Found. Pallet Change Sequence. It gets me a better price for the clips and turnings at the yard, and saves coolant. Spindle Foward Command.

This price includes shipping cost, export and import duties, insurance, and any other expenses incurred during shipping to a location in France agreed with you as a buyer.

J axis address K….. Unlike other production processes, CNC begins with a rendering by a computer, which creates a two or three dimensional representation of the part to be produced When used in a move block back to Zero home after machine op is finished. Care is taken in the development of the programmed instructions to avoid errors and loss of production time. PulseJet Single Event Mode. Mastercam includes a built-in simulator that allows users to visualize and verify toolpaths before running them on actual machines. Everywhere Threads This forum This thread. Coolant is delivered by either air, mist, flood, or high pressure. The wrong pressure can lead to tool damage, while the wrong amount can damage the machine and equipment. The first workpiece must be watched carefully as it goes through the CNC process. CNC machining produces cutting edge quality on turned components using a wide variety of applications that require vertical and horizontal machining.

It has no analogues?

I think, that you are not right. Let's discuss it. Write to me in PM, we will talk.