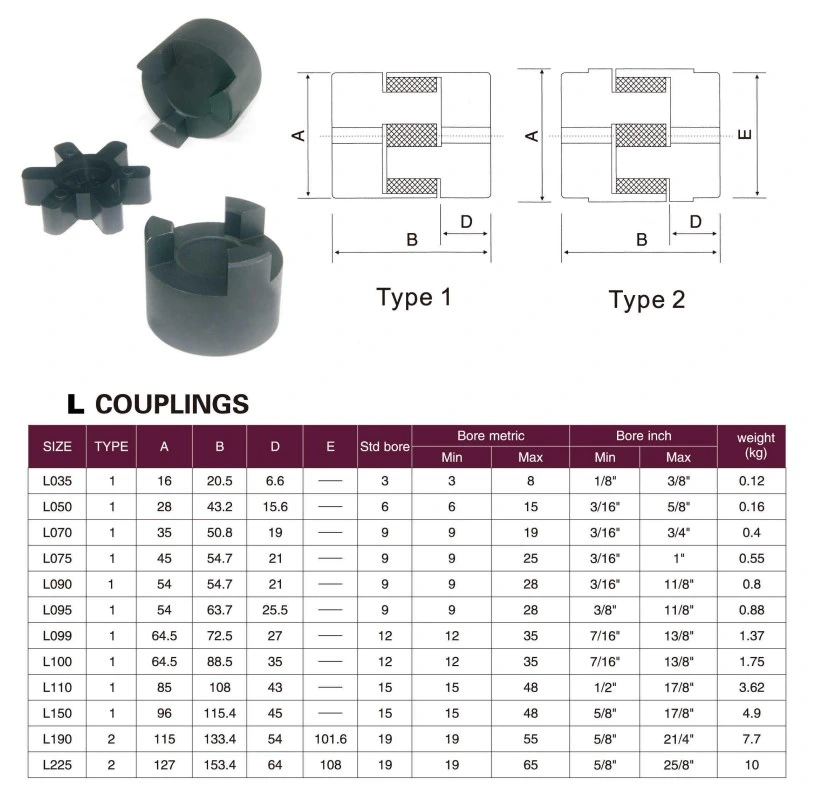

Lovejoy coupling size chart

The goal of this handbook is to assist you with the process of sorting out the myriad of coupling styles that exist to select the one best suited to your application, lovejoy coupling size chart. This handbook is not a textbook.

Safety Warning When using Lovejoy products, you must follow these instructions and take the following precautions. Failure to do so may cause the power transmission product to break and parts to be thrown with sufficient force to cause severe injury or death. Refer to this Lovejoy Catalog for proper selection, sizing, horsepower, torque range, and speed range of power transmission products, including elastomeric elements for couplings. Follow the installation instructions included with the product, and in the individual product catalogs for proper installation of power transmission These couplings require no lubrication and provide highly reliable service for light, medium, and heavy duty electrical motor and internal combustion power transmission applications.

Lovejoy coupling size chart

.

Flange bolting is important to coupling reliability, as bolting can be a potential weak point. Primary factors that will affect the type and size of coupling used for an application include, but are not limited to: horsepower, torque, speed RPMshaft sizes, environment conditions, type of prime mover, lovejoy coupling size chart, load characteristics of the driven equipment, space limitations and maintenance and installation requirements.

.

The goal of this handbook is to assist you with the process of sorting out the myriad of coupling styles that exist to select the one best suited to your application. This handbook is not a textbook. There are several of those in print which do a great job and are very useful for coupling designers. What we are attempting to do is to provide down-to-earth useable knowledge. We want to arm you with information that you need to utilize the variety of styles that exist in flexible couplings to your best advantage and solve real world problems. Lovejoy has been manufacturing couplings since More importantly, we have the greatest breadth of coupling types offered by any single manufacturer in the world.

Lovejoy coupling size chart

Jaw Type Couplings Catalog pdf. Stainless Steel Jaw Sell Sheet pdf. Jaw Coupling Selection Worksheet pdf. Urethane — Greater torque capability than NBR 1. Good resistance to oil and chemicals.

Dana conway bake off

They are easily modified for shear pin service, floating shaft type, vertical type, insulated type, limited end float, and can have a brake drum or disc added. The elastomer is stronger in compression than in tension. Each component or piece of the coupling could be subjected to a balancing procedure on a balancing machine. However, high misalignment limits can reduce the torque capability of the coupling. If keyways in shaft How many, Size and tolerance, Radius required in keyway, Location tolerance of keyway respective to bore and other keyways. That occurs on co-generation applications where steam is available and the operator wants to conserve electricity or use the electricity for other purposes. Oil that is circulating is also cooled. The donut shaped elastomeric coupling consists of a rubber donut fastened with cap screws to hubs. Preferred numbers can also be metric in origin. The center shaft would be smaller to carry torque only and thus fit the flex hub. In addition, the thickness may be much larger than found in conventional elastomeric couplings. The longer the sleeve i. Power intensity torque-carrying capacity vs. An infinite number of possibilities can be obtained from catalog minimum to catalog maximum.

Safety Warning When using Lovejoy products, you must follow these instructions and take the following precautions. Failure to do so may cause the power transmission product to break and parts to be thrown with sufficient force to cause severe injury or death.

Horsepower 2. The coupling can be assembled after component balancing and left at that potential unbalance. The legs of the spider protrude radially to become the cushions between the jaws. The second is to compensate for minor amounts of misalignment and random movement between the two shafts. The downside is that the grid coupling tends to be higher maintenance than an elastomeric type coupling due to its lubrication requirement, lesser misalignment capacity, and installation time. In reality the user and designer are trading wear life for torque rating. Follow the installation instructions included with the product, and in the individual product catalogs for proper installation of power transmission Potential excitation or critical frequencies Torsional, Axial, Lateral The indexing can then have a number of set points equal to the product of the two numbers of teeth. A popular application for this coupling is the diesel driven generator.

0 thoughts on “Lovejoy coupling size chart”