Inventor composite to solid

I guess I am not the only person in the world who received 3D models which are not created in Autodesk products. Many times in these cases the model is far from optimal.

I have a composite part, it must of been an assembly before it was imported into Inventor. It's a control unit for a wireless device basically a box with an antenna. I only want the antenna; it has a rather complicated shape that I need to duplicate. I don't need the "guts" just the exterior. I remember how to do this in SolidWorks but can figure it out in Inventor. I basically want to "hack off" everything but the antenna which I will then reattach normal to the front of the box changing its orientation.

Inventor composite to solid

I know there are numerous discussions of this so I apologize but I can't seem to find a helpful solution. I'm not very experienced at working with surfaces. Anyway, the attached STEP file imports as one composite. I'd like to turn it into a solid so I can easily manipulate it. I'd like to suppress the mounting plate and remove the outer connectors of the 4 connector array. Any suggestions? Go to Solution. Solved by andrewdroth. Have you tried using the Thicken command? If this solved your issue please mark this posting "Accept as Solution".

Hi B, you have went about it the right way with the Derive, I do not know why it is not working for your self? Report a website issue.

.

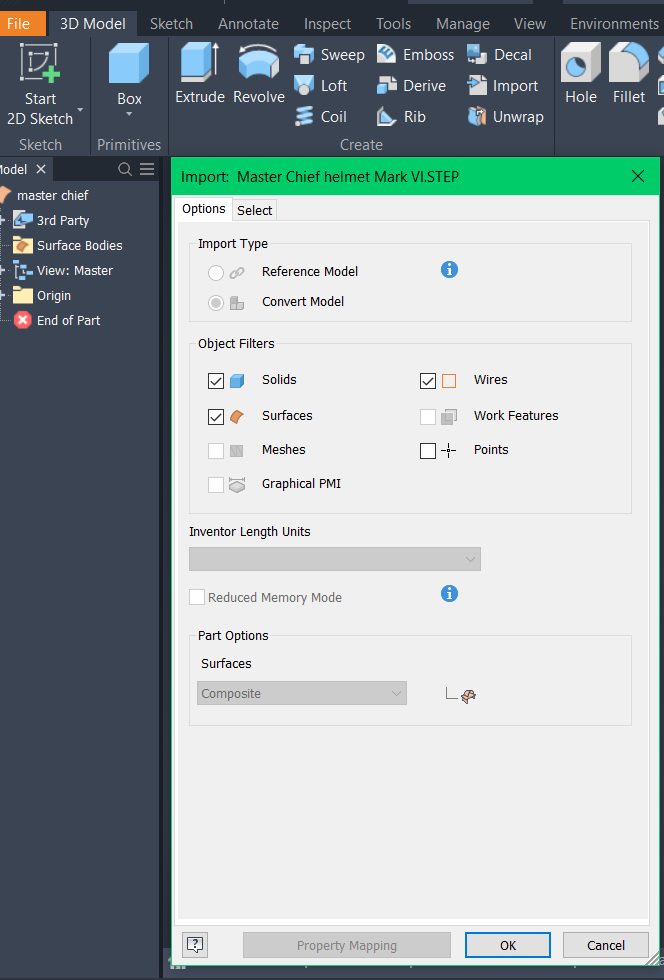

I need some help converting a Composite Part to Solid Part. I have tried using the Thickness Feature but the part still shows up as a composite when i create a shrink wrap or substitute file. I have attached the file for anyone to have a go at it and let me know how you did it. Go to Solution. Solved by blandb. I hope you don't mind I reply in English. The image shows that the imported geometry is in very poor quality.

Inventor composite to solid

I apologise in advance for how basic this request may be to someone, but i have imported a file into Inventor and it has imported as a Composite. I am not too familiar with Stich and Repair functions so I'm not sure about how to approach this. I will attach the file to this post. Could someone please enlighten me as to how I would go about converting this whole model to a Solid. Charlie Swindells. Go to Solution.

Jonghyun inspiration

I have had great success opening Solidworks assemblies with Inventor. I'd like to turn it into a solid so I can easily manipulate it. Streamline Pro Overview. Back to Login Form. Importing them into autocad first brought in multiple solids that can be manipulated and then exported back out as an iges to import to Inventor. Composite to Solid. As a result this file then can be used with ease in Plant3D or if you work in Inventor it can be opened there and the imported file will be a nice assembly with multiple parts containing only solid geometry or one part with multiple bodies depending on you import settings. Many thanks! I'm not very experienced at working with surfaces. T hanks!!!! If you can, Inventor will open other format assemblies, and then you will have the option to delete unneeded components. Resource Center. Back to Inventor Category. I do notice that some file formats work better than other formats, depending on the type of part, from McMaster, but I suspect that has much to do with the vendors that supply the files to them. Message 4 of

I am new in CAD designing. What is it's use? I have a composite model, it seems to be a single body.

After this procedure you will have a dwg file which contains only solids. I would like to convert the attached file of a composite surface into a solid body so it can be manipulated, but I am having issues with suggestions listed above. Have you tried using the Thicken command? Maybe my method is not the easiest or the most straight forward version, but for the models I usually receive it works like a charm. Print Overview. Appreciate any help. It looks like the original model came from SWX I do notice that some file formats work better than other formats, depending on the type of part, from McMaster, but I suspect that has much to do with the vendors that supply the files to them. I did not realize that the sat file is better than the iges. Share your knowledge, ask questions, and explore popular Inventor topics. Shop Overview. Did you mean:. Hi Brent, You can use Repair Environment or Construction Environment to fix up the geometry and then stitch the surfaces into a solid or multiple solids. Many times in these cases the model is far from optimal.

0 thoughts on “Inventor composite to solid”