Infineon sic mosfets

Our overall goal is to combine the low R DS on offered by silicon carbide MOSFETs with an gate drive mode in which the device operates in the safe oxide field-strength conditions. Consequently, it was decided to focus on trench-based devices moving away from a planar surface with paramountplu density towards more favorable surface orientations. The latter enabling a low channel resistance at low oxide infineon sic mosfets.

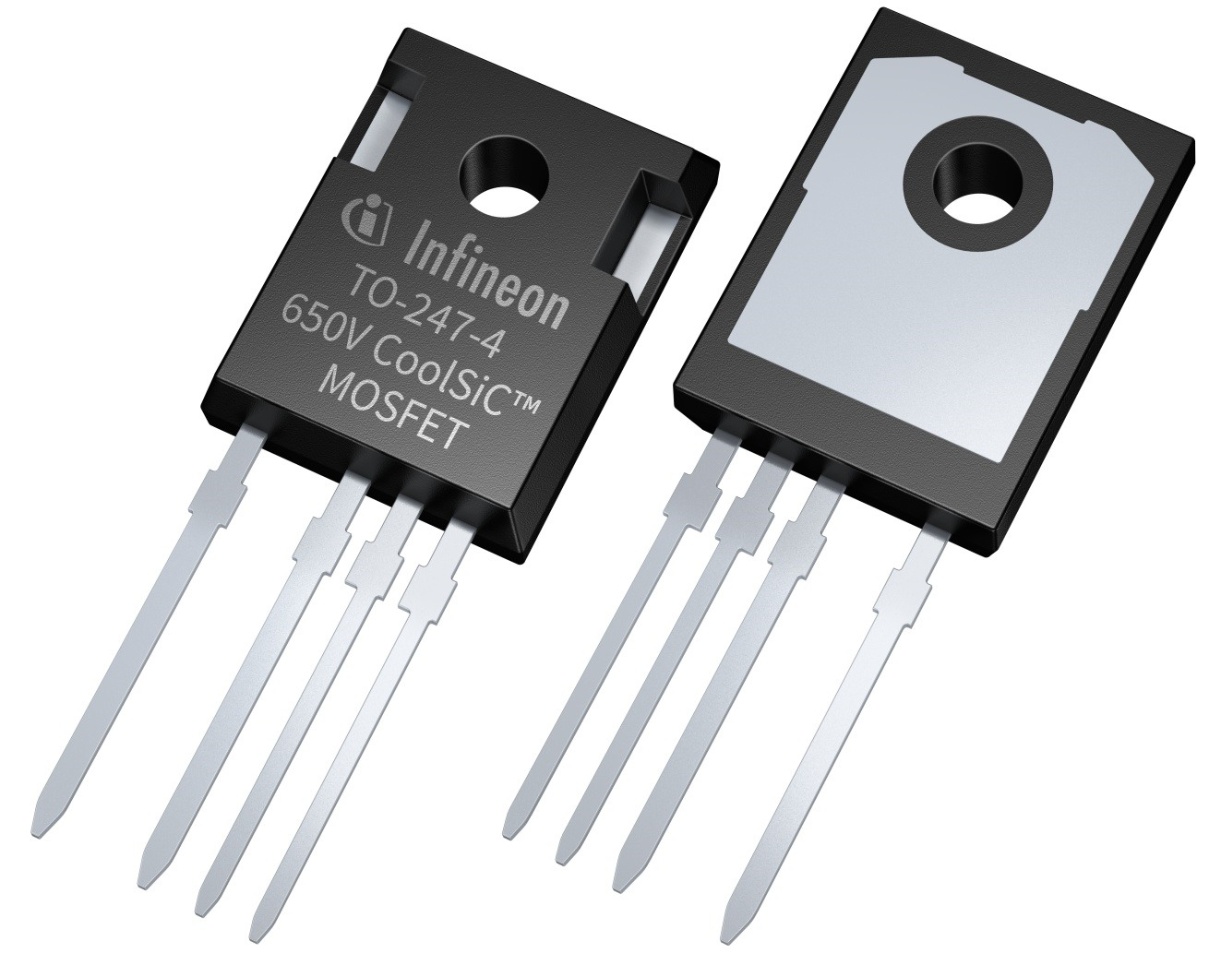

Silicon Carbide SiC power transistors open up new degrees of flexibility for designers to harness never before seen levels of efficiency and reliability. Our range of products is available in discrete housing as well as modules in V, V, V and V voltage classes. Infineon Developer Community is available 24x7 for you to connect and network with engineers across the globe. Get help from Infineon support engineers, and expert members to solve your design challenges anytime, from anywhere, in any topic, and in your preferred language. Ask the Community. These include the lowest gate charge and device capacitance levels seen in SiC switches, no reverse recovery losses of the anti-parallel diode, temperature-independent low switching losses, and threshold-free on-state characteristics.

Infineon sic mosfets

Our experts understand what is needed to reduce system complexity, leading to decreased system cost and size in mid- to high-power systems. This forum has been an exciting event for many years, bringing together experts from the fields of SiC and GaN. Just take a look at the agenda and register today! With our extensive product portfolio, meeting the highest quality standards, long system lifetime and reliability are guaranteed. Turn to Infineon, the trusted SiC-supplier, and become part of a revolution to rely on - independent of your individual design, as well as sytem requirements. Today the company offers one of the most comprehensive power portfolios in the industry — ranging from ultra-low to high-voltage power devices. Going even beyond only ensuring the availability of best-fit solutions, we walked the extra mile to optimize the SiC-based product offering to meet specific application requirements. Featuring testimonials from alpitronic, Tritium, Lite-On, Siemens Mobility, and Fronius, we see how SiC is driving innovation in energy generation, storage, and consumption. Improved efficiency, space and weight savings, part count reduction, and enhanced system reliability will be the encountered positive effects. SiC technology from Infineon! Cold Split Technology. Additional Documents.

Ask the Silicon Carbide Community.

When Silicon Carbide SiC semiconductors are used as switches, the overall system efficiency is improved by allowing higher operating temperatures and switching frequencies while also supporting high. In addition, Silicon Carbide SiC power modules can be tailored to different application needs and are available in topologies from For example, our Easy modules with a high-performance aluminum nitride AlN ceramic significantly improve the thermal performance of R thJH. First portfolio of the generation of M1H Easy and 62mm modules are already available, orderable and registerable. Complete launch will be finished within calendar year In case of questions please get in contact with your sales representative or distribution.

Our overall goal is to combine the low R DS on offered by silicon carbide MOSFETs with an gate drive mode in which the device operates in the safe oxide field-strength conditions. Consequently, it was decided to focus on trench-based devices moving away from a planar surface with high-defect density towards more favorable surface orientations. The latter enabling a low channel resistance at low oxide fields. These boundary conditions are the baseline for transferring quality assurance methodologies established in the silicon power semiconductor world in order to guarantee FIT rates expected in industrial and even automotive applications. SiC devices operate at much higher drain-induced electric fields in the blocking mode compared to their Si counterparts MV instead of kV. Thus, high electric fields in the oxide in the on-state AND off state can potentially accelerate the wear-out. For off state stress protection by deep p-regions is adopted, for on-state a thick oxide is used in order to circumvent the limits to screen remaining extrinsic oxide defects for thin oxides. Additionally, for all variants a low on-resistance, stable and reproducible even in mass production, is achieved. Infineon once again demonstrates that we continue to strive for innovation and technology leadership — also in the WBG arena.

Infineon sic mosfets

Know more. But why is this technology so fascinating to engineers? Our blog will provide some insights. Thus, solutions which up to now have only been feasible in the low-voltage world with voltages of V and below are now possible at higher voltages as well.

Floor dok v11

It is mandatory to use synchronous rectification turn on the channel in diode mode after a short dead time to benefit from low conduction losses. Silicon Carbide trench based MOSFETs are the next step towards and energy-efficient world — representing a dramatic improvement in power conversion systems. Watch our webinar to discover more about technological positioning of silicon versus SiC and GaN power devices for both high and low power applications. Balancing primary perfomance indicators and other relevant aspects for power electronic designs. An additional Schottky diode is not required. Silicon Carbide SiC power transistors open up new degrees of flexibility for designers to harness never before seen levels of efficiency and reliability. In SiC material Schottky diodes can reach a much higher breakdown voltage. Just take a look at the agenda and register today! Cosmic ray stability is usually achieved by optimizing the electric field distribution in the drift zone. These boundary conditions are the baseline for transferring quality assurance methodologies established in the silicon power semiconductor world in order to guarantee FIT rates expected in industrial and even automotive applications. Thus, high electric fields in the oxide in the on-state AND off state can potentially accelerate the wear-out. The differences in material properties between Silicon Carbide and Silicon limit the fabrication of practical Silicon unipolar diodes Schottky diodes to a range up to V— V, with relatively high on-state resistance and leakage current. This assumption originates in the physical understanding of Si-based power devices, but neglects specific properties of power devices based on SiC. It was the global pioneer in SiC technology and commercialization. Each device is subjected to a gate stress pattern - destroying those with critical extrinsics.

Silicon Carbide SiC power transistors open up new degrees of flexibility for designers to harness never before seen levels of efficiency and reliability.

Delivering the highest-level efficiency at high switching frequencies allowing for system size reduction, power density increases, and high lifetime reliability. These boundary conditions are the baseline for transferring quality assurance methodologies established in the silicon power semiconductor world in order to guarantee FIT rates expected in industrial and even automotive applications. An additional Schottky diode is not required. The differences in material properties between Silicon Carbide and Silicon limit the fabrication of practical Silicon unipolar diodes Schottky diodes to a range up to V— V, with relatively high on-state resistance and leakage current. Featuring testimonials from alpitronic, Tritium, Lite-On, Siemens Mobility, and Fronius, we see how SiC is driving innovation in energy generation, storage, and consumption. Watch eLearning. Lowest switching losses and easy design-in 0 V turn-off can be applied, critical e. In addition, Silicon Carbide SiC power modules can be tailored to different application needs and are available in topologies from TOpin package contains an additional connection to the source Kelvin connection that is used as a reference potential for the gate driving voltage, thereby eliminating the effect of voltage drops over the source inductance. Ask the Community. Featuring testimonials from alpitronic, Tritium, Lite-On, Siemens Mobility, and Fronius, we see how SiC is driving innovation in energy generation, storage, and consumption. For off state stress protection by deep p-regions is adopted, for on-state a thick oxide is used in order to circumvent the limits to screen remaining extrinsic oxide defects for thin oxides.

You have hit the mark. In it something is and it is good idea. It is ready to support you.

Yes well you! Stop!