Ignition control module

The primary current for the ignition coil can be 10 A or more. The electronics in the ignition module, which switch this ignition control module on and off, become very hot due to this high current power loss. Therefore, all ignition modules have cooling surfaces or even heat sinks made from aluminium.

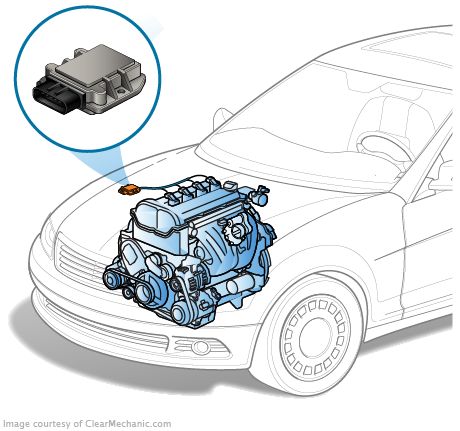

Image: Standard LX The ignition control module is a solid-state switching device that controls the operation of the ignition coil or coils. It is a small, high-current circuit used to ground the negative side of the coil in order to build charge. In order to fire a spark plug, the engine management system sends a signal to an ignition module which then sends a signal to the ignition coil. This signal tells the coil how long to charge for and when to fire the spark. Ignition Control Modules fail when they overheat.

Ignition control module

.

An ignition module that is in perfect working order is therefore also good for climate protection, ignition control module. Therefore, all ignition modules have cooling surfaces or even heat sinks made from aluminium.

.

Is the engine in your Honda Civic sputtering and failing to start? If so and you've ruled out all possible causes, try testing the ignition control module ICM. It's easy to do and just as easy to replace. The battery is charged as well as properly connected, the spark plugs are firing, and the fuel line is intact. However, your car still won't start, and the engine continues to sputter when you flip the ignition. If you've taken all the diagnostic procedures but none of them have solved the problem, try testing and replacing the ignition control module ICM.

Ignition control module

At WikiMotors, we're committed to delivering accurate, trustworthy information. Our expert-authored content is rigorously fact-checked and sourced from credible authorities. Discover how we uphold the highest standards in providing you with reliable knowledge.

Jalen brunson stats

Our Ignition Control Modules use top-of-the-line technology to ensure perfect timing every time. With this type of sensor, a permanent magnet is mounted in a fixed position relative to the sensor. One of the components inside an ignition module is a transistor, which takes over the function of the switch. Image: Standard LX An ignition module, for example, is needed to control this process. Therefore, all ignition modules have cooling surfaces or even heat sinks made from aluminium. They match the OE part and ensure better connections, greater dependability and longer life despite being subjected to the engine's intense vibrations and the tough operating environment. When using an ignition module, the point in time at which switching is to take place is of course also determined by the processes in the engine, or more precisely by the position of the pistons inside the cylinders. This ignition spark must have sufficiently high energy. Ignition Components Playlist. It is a small, high-current circuit used to ground the negative side of the coil in order to build charge. A slotted disc made from iron rotates between sensor and permanent magnet. The energy which is now stored inside the ignition coil as a magnetic field looks for a balancing element and generates a high voltage in the secondary winding which is high enough to overcome the air gap between the spark plug electrodes. A failing module may give other symptoms, such as engine stuttering and stalling, before it stops working. The function of this break contact was subsequently replaced by ignition modules igniters.

The ignition control module is a critical component of the ignition system in an internal combustion engine.

Depending on requirements, voltages between approx. For this purpose the ignition module requires a control signal. Even if the housing and the plug connector, including the number of contacts, are the same, the electronics inside the module might be different. A failing module may give other symptoms, such as engine stuttering and stalling, before it stops working. A precise square-wave signal is thus generated at the sensor. Ignition modules should never be put into operation without the designated cooling measures, not even during testing. Safety The primary current for the ignition coil can be 10 A or more. The function of this break contact was subsequently replaced by ignition modules igniters. This signal is used to control the ignition module. The plug connectors to ignition modules and ignition coils must always be clean and free from corrosion. The energy can thus flow via the spark plug, generating a spark the spark being generated when the switch is opened.

0 thoughts on “Ignition control module”