Horizontal boring machine line diagram

Download Now Download to read offline. Recommended Single Point Cutting Tools. Boring machine.

Horizontal 2. Vertical 3. Horizontal boring machine Milling, Grooving a. Floor Type c. Vertical Boring machine castings, fly wheels and circular parts a. Precision boring machine 4.

Horizontal boring machine line diagram

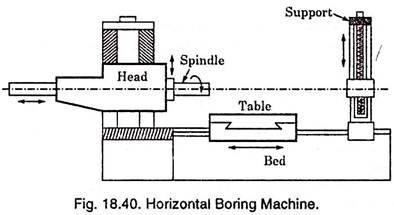

A boring machine is a machine which is used for boring large holes on the articles or work items which are not possible to move or rotate on the machine. It is one of the most useful machines which is used on heavy articles like engines, frames, cylinders, land etc. Horizontal boring machines are used to bore large holes in a horizontal direction. Horizontal boring machine is the heavy duty machinery which is used for the boring on large work items which are more in immovable nature, heavy, difficult to balance etc. And it performs multiple tasks like boring, turning, milling, cutting, grinding etc. The main difference between the vertical boring machines and the horizontal boring machine is the machine installation and configuration pattern. That means the positioning of operation tools and the placement of work item. In the vertical type of boring machine configuration, the operational tool is placed like normal lathe machinery and performs all the normal lathe machinery functions like cutting, turning, boring, threading etc. Uses- Vertical boring machines are used in turbines, tires, pipelines, large frames, machine tables etc. Horizontal boring machine is basically used when boring operation is to be performed on larger parts. In this machine, the spindle is positioned in horizontally and the spindle is placed in the parallel position to the table and ground both. Uses- Horizontal boring machine is used in boring, shaping, facing, milling and drilling. One of the major uses is when parts are larger in size and crane is to be placed overhead. Horizontal Boring Machine remains static and the boring tool is rotated.

Download Now. Umair raza. Umair raza Umair Raza.

Toll free Mills and lathes are highly versatile machine tools that form the centerpiece of most machine shop floors. Boring mills, on the other hand, are more specialized, meaning they frequently appear as part of a larger production line. The easiest way to describe what a boring mill does is to say that a boring mill drills holes. The reality is slightly more complex. Boring mills are more frequently used to enlarge holes that have already been drilled. While standard mills and lathes can also be used to rough out or finish boring holes, boring mills provide extra power and stability.

The Engineers Post. Its parts, types, tools and operations. In order to better assist you in understanding, we will go over every aspect of the horizontal boring machine in this article. The boring machine is one of the most versatile machine tools used to bore holes in large and heavy parts such as engine frames, steam engine cylinders, machine housing, etc. Which are practically impossible to hold and rotate in an engine lathe or in a drill machine.

Horizontal boring machine line diagram

So, there are mainly 3 types of Horizontal Boring Machines —. The most versatile machine out of these above mentioned is the first one i. So, it is the most commonly used and universal type. A Horizontal Boring Machine has a work spindle parallel to the ground and work table. The tool head and part move typically along three linear axes. The main axis that drives the part towards the work spindle is the Z-axis, with a cross-traversing X-axis and a vertically traversing Y-axis.

Storage bags for clothes

Double cutters are wide to a great in production boring as the machining time is reduced to a great extent compared to that of a single-point fly cutter. Ipec shaper and planer Manoj Yadav. Broaching machine AliRaza The headstock supporting column and the end supporting column are mounted on the runways which are placed at right angles to the spindle axis. Manikanta Demudu. Recommended Single Point Cutting Tools. Ordinary boring operations are carried out with tools mounted on a bar held in a spindle having a morse taper hole. Grinding Machines Konal Singh. Boring Operations. Boring Machine Boring Machine. The end of the supporting column and headstock supporting column may adjust towards or away from the table to accommodate different widths of work.

Horizontal Boring Machine:. The horizontal boring mill is also known as horizontal boring, drilling and milling machine, and is intended to perform operations on relatively large pieces which cannot be rotated easily, are irregular and unsymmetrical, and require operations on many surfaces.

He completed his engineering studies in and is currently working in a large firm as Mechanical Engineer. Loading Comments What's hot 20 Shaping , slotting and planning machines. Boring Machine Mechanism. By the fitting of simple attachments, the use of the machine can extend still further to include screw cutting, turning , planetary grinding , or gear cutting. Pointers and Array, pointer and String. What is Boring Machine? Horizontal Boring Machine remains static and the boring tool is rotated. MECH naanmech Subscribe to our newsletter to receive our blog post directly to your inbox. Type your email… Subscribe. A bed is made of cast iron and affixed on the ground. This type of machine is appropriate for general-purpose tasks where it is necessary to carry out more operations in addition to boring.

I agree with told all above.

You are mistaken. I can prove it. Write to me in PM, we will talk.

Also that we would do without your magnificent phrase