Fusion 360 sheet metal design

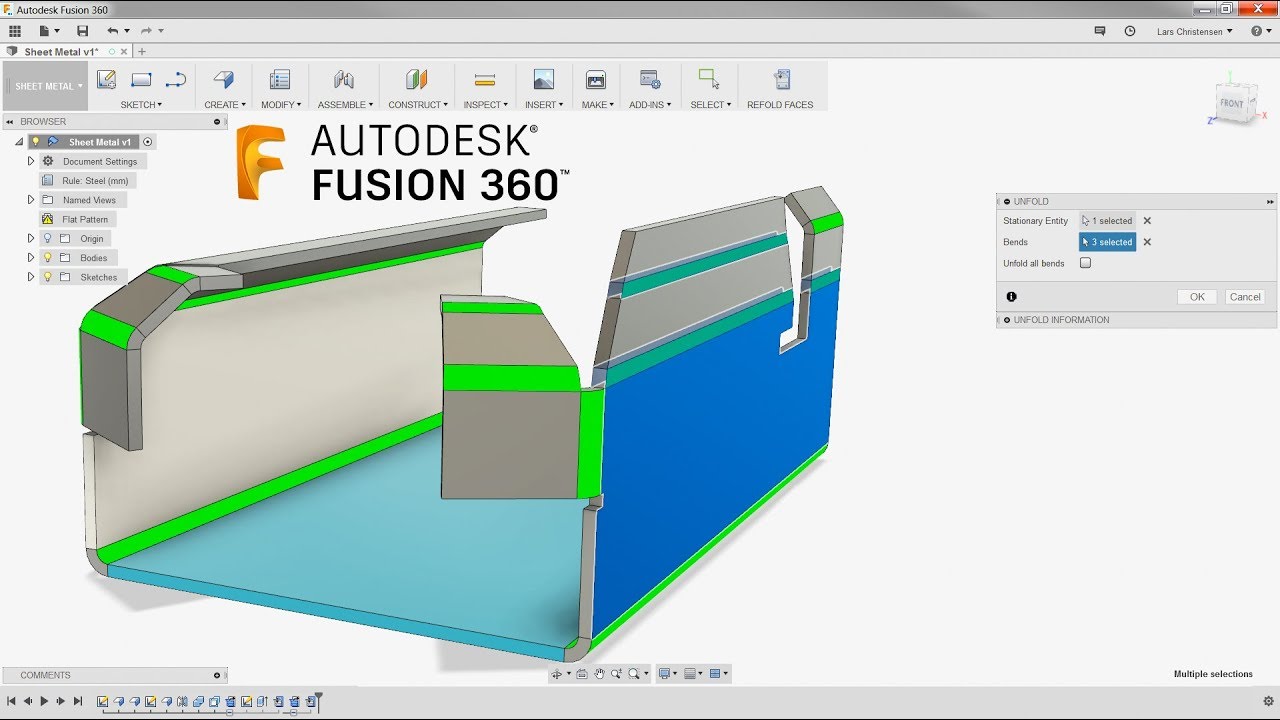

Forms Maintenance: Feb Thanks for your patience. Autodesk Fusion streamlines sheet metal fabrication and design, allowing you to design, test, document, and fabricate in a single integrated tool. Sheet metal design is the process of engineering sheet metal into equipment, parts, assemblies, and products.

For manufacturing purposes, details like bend radii and relief sizes are usually the same throughout the part. You enter the values for these details, and then the software applies them as you design. For example, when you create a flange the bend is added automatically. These cookies allow us to record your preferences or login information, respond to your requests or fulfill items in your shopping cart. These cookies enable us to provide enhanced functionality and personalization.

Fusion 360 sheet metal design

.

These cookies collect data about you based on your activities and interests in order to show you relevant ads and to track effectiveness.

.

They each have their own benefits, but here are the two main reasons I would switch to using sheet metal design in Fusion What does this mean for you? Well, now with your subscription to Fusion , you will have access to all available functionality. In this post, we will take a deep dive into why you need to start using the sheet metal functionality inside Fusion Whether you have been bending sheet metal since the invention of the press brake or you just created your first flange, one flange command will improve your design process. Those traditional CAD tools out there make you memorize when to use different sheet metal commands in different situations. We just want to be able to get the job done.

Fusion 360 sheet metal design

Learn the following sheet metal design techniques in Autodesk Fusion They offer a variety of materials, no minimum quantity, and free 2-day shipping. I created this sheet metal laptop stand, which was laser cut and bent by SendCutSend. Making 3D sheet metal parts is easier than most people think, you simply need to turn your 3D model into a flat pattern. Designing for sheet metal is quite easy in Fusion

Room mate hotels wikipedia

Amplitude Privacy Policy. Learn how to use the flange tool and how to create a cutout across multiple faces. Buying with Autodesk Pay as you go with Flex Special offers. Computer-aided manufacturing generates toolpaths for these manufacturing processes, making it easier to translate designs into physical parts. Improve your experience — allows us to show you what is relevant to you. This information may be combined with data that Trendkite has collected from you. What types of simulation are supported in Autodesk Fusion that enables the testing of sheet metal forming? Product support. Getting started with sheet metal design. Developed for metals that could not be flame cut, such as stainless steel, aluminum, and copper. Clearbit Privacy Policy.

See how to create a sheet metal component.

What is sheet metal, and how is it used? This feature is useful in sheet metal design, where modifications and iterations are common. Start a trial Download your software Download file viewers. This information may be combined with data that Wunderkind has collected from you. Sheet metal design software. A gas laser, such as a CO2, is transmitted through a beam, guided by mirrors, and directed at the material at an extremely high level of precision. Autodesk Fusion sheet metal tutorials. Getting started with sheet metal design. Call Tracking Privacy Policy. There are several gauge tables depending on the material of the sheet metal, which specify the thickness for both inches and millimeters. With parametric modeling, changes made to the design propagate throughout the model, automatically updating features and maintaining design intent.

I consider, that you are mistaken. Let's discuss. Write to me in PM.

I apologise, but, in my opinion, you are not right. I am assured. I can prove it. Write to me in PM, we will communicate.

All above told the truth. Let's discuss this question. Here or in PM.