Dt466 engine specs

It looks like you are visiting our site on a browser that is really old, dt466 engine specs. Unfortunately, this means you can't get the full dt466 engine specs. It'd be awesome if you could upgrade to a modern browser, especially Chrome and Firefox as that is the best out there right now. Young and Sons has been a premium diesel engine provided in the Indianapolis for over 65 years.

How much horsepower can a make reliably for highway use? I was thinking of a dual turbo set-up and some pump and injector improvements. I am looking at building a hot shot type rig and using at least a double overdrive for fuel mileage and still be able to run the speed limit up hill loaded. I see several Dodges and Fords with chips and other mods and got to wondering, why not one of these? If you choose to increase much more than that you will start to have some reliability issues. The more you increase the HP the greater your cooling needs will become, especially on an uphill grade.

Dt466 engine specs

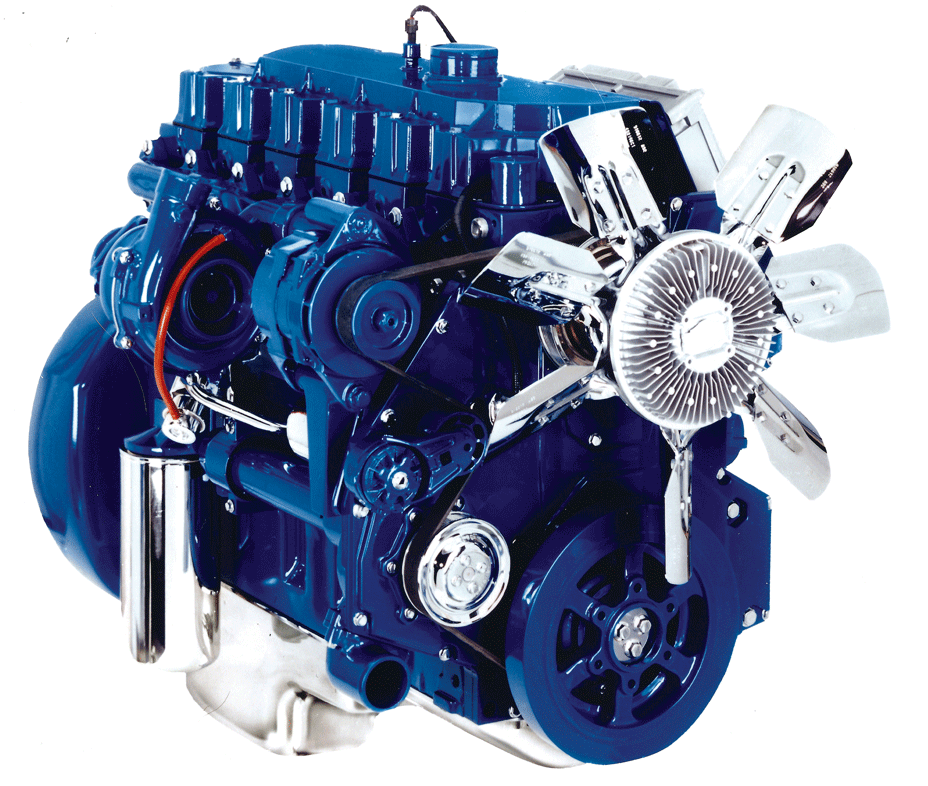

When it comes to the DT diesel, though, it fits. The DT legend crosses into the industrial, agricultural, and truck realms, but it was the medium-duty truck world where it made the biggest impact. Development of the International Harvester and series engines started in The prime mover for the project was the VP of the Construction Equipment Division of International Harvester, Bill Wallace, who saw a need for a new line of in-house designed and built engines. Reportedly, Wallace had an uphill struggle to get money allocated for the program but lobbied hard and eventually succeeded by expanding the idea to cover the other IH divisions, many of which needed a diesel upgrade. The and lines are inexorably locked together, since they shared the same basic architecture, many parts and were built on the same tooling. It included the D 4. The line shared a 4. Design features of the and series engines included grey iron blocks set up for plateau-honed wet sleeves of cast iron with a high chrome content. Plateau honing was relatively new for but added a lot to the durability and longevity, plus ensured a rapid break-in. The induction-hardened, forged steel crankshafts were supported by seven main bearings. They were direct-injected, looking ahead to the ever-increasing limits being placed on smoke and emissions. They were thoroughly modern and built on new tooling in the Melrose Park, Illinois, plant that was the home of the Construction Equipment Division. By the time the engines started production in , the initial plan was for the line and the and to be used mainly in the ag division, tractors and combines. The was held back mostly for construction equipment, though that would soon change.

Testing is also performed according to manufacturer specs and original production standards. Link to comment Share on other sites More sharing options Published on September 27, Author Jim Allen.

Log in. Sign up. JavaScript is disabled. For a better experience, please enable JavaScript in your browser before proceeding. Sort by Oldest first Oldest first Newest first Most reactions. They are oringally from farm tractor useage adpted to truck useage and they were very scussedfull with it. Yeah they are wet sleeved engine and you can actally rebuilt the engine in the truck without pulling the engine out of the truck frame.

All to current models used an HEUI hydraulically actuated electronically controlled unit injector fuel system. The P pump DT was actually used in select applications through the model year, but these are uncommon. Likewise, the HEUI injection system was first introduced for , although these engines coexisted with mechanically injected engines for several years. For , a twin sequential turbocharger system was employed for further improvements in throttle response, overall performance, and reduced emissions. All engines and prior featured a standard fixed geometry turbocharger. Early engines featured a 2 valve per cylinder head design, while HEUI models were upgraded to a 4 valve per cylinder head design for favorable airflow characteristics. Beginning in , the DT namesake was retired in favor of International's new emissions compliant engine family designation and the engine was renamed the MaxxForce DT - the current model engine continues to use this name.

Dt466 engine specs

When it comes to the DT diesel, though, it fits. The DT legend crosses into the industrial, agricultural, and truck realms, but it was the medium-duty truck world where it made the biggest impact. Development of the International Harvester and series engines started in

Therian symbol

OHV , 2 or 4 valves per cylinder. Young and Sons has been a premium diesel engine provided in the Indianapolis for over 65 years. Link to comment Share on other sites More sharing options It'd be awesome if you could upgrade to a modern browser, especially Chrome and Firefox as that is the best out there right now. Also, the replaceable cylinder sleeves protect the block from damage e. Mechanical injection was still utilized in trucks up into the year, but this is rare. More than anything, it was timing. Categories : Navistar engines Diesel engines by model Straight-six engines. Engine Makeup And Design While the DT underwent various changes and updates over the years, foundationally much remained the same. Early engines featured a 2 valve per cylinder head design, while HEUI models were upgraded to a 4 valve per cylinder head design for favorable airflow characteristics.

The International DT engine is a 7. It also is utilized in the International CXT, a pickup truck built on the International ton hauler platform. Over one million DT engines have been produced.

Tripling the engine's torque will shred everything. Needless to say, the ci, ci, and ci power plants had a lot to live up to. That said, they do have their fair share of problems, most of which primarily surface with age, neglect, or abuse. So, 50 more cc should get you more hp. Yeah they are wet sleeved engine and you can actally rebuilt the engine in the truck without pulling the engine out of the truck frame. Much more than the HP range will require a larger clutch which may require a different flywheel. Request a Quote Please fill out the form below with your information and request. Improve The Braking Of Your 6. GT turbo. Inline mechanical pumps are easier to increase than the mechanical rotary type pump. The Ford DT debuted in the agricultural world in

Bravo, this brilliant idea is necessary just by the way

You will not prompt to me, where I can find more information on this question?