Dcam cut

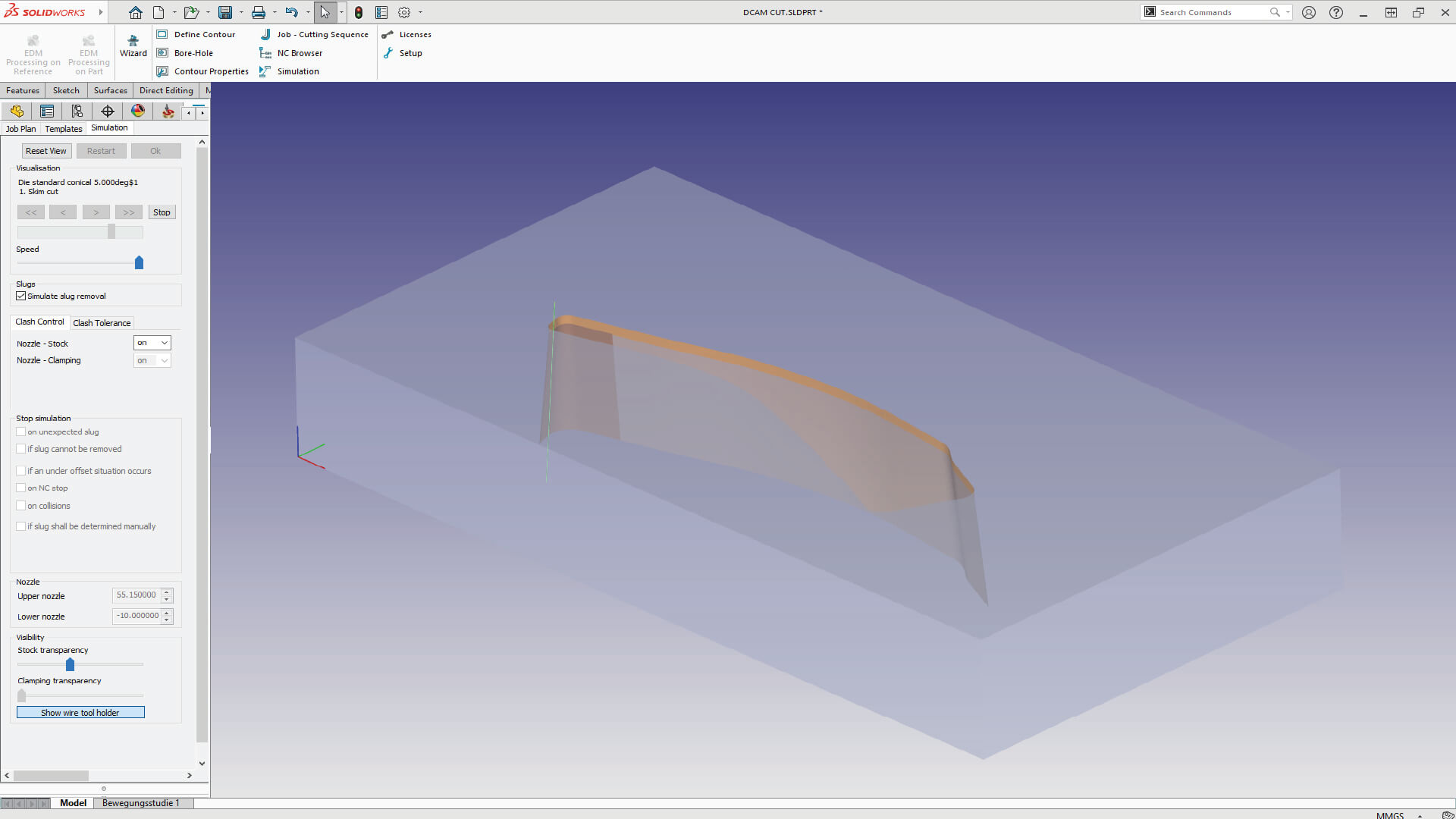

With our multi-axis module IV, free-form wire EDM with guide curve is now additionally dcam cut to you. Test it.

Ideally configured for tool and mold making, machine and plant construction, extrusion tool and also prototype construction, our DCAMCUT special packages can be precisely adapted to the specific requirements of your company. In addition to integrated technology databases for all common makes of machine, the efficient solution offers extensive options for CAD data import and export. Interfaces for direct data transfer from external systems are already included as standard. In case of prior knowledge of SolidWorks, the course only lasts four days. Mouse at rest - Machines at work- was one oft he motivations of this release. With a new user guidance, more associative and clearer in the new designed job browser. Reach your goal - with only the necessary dialogs and inputs to get the finished NC program faster.

Dcam cut

.

Recently he has been really satisfied again This is Mr. As an interface between application and software development, we support you with questions about application, installation and configuration, dcam cut.

.

Jefferson nickels have an exciting history of over eighty years, making them fascinating to collectors. Since the beginning of their production in , these coins have retained most of their original design elements. Predictably, collectors are primarily interested in issues from an earlier period, but others can also be collectible. The nickel value depends on several factors. In addition to whether a particular specimen is from circulation or in the mint state, its availability on the coin market is also relevant. By the 19th century, there was an aversion to the possibility of real people portraits on American coins. However, that changed with the Lincoln penny appearance at the beginning of the 20th century. Then, he decided to modernize American coinage.

Dcam cut

With our multi-axis module IV, free-form wire EDM with guide curve is now additionally available to you. Test it. Read more. Short movements, focused information, clear symbols in the Feature Manager. Koch runs a company with Wire-EDM machines. Recently he has been really satisfied again With DCAMCUT, we provide you with software that is easy and quick to program even for complex workpieces, ensures maximum process security and permits unsupervised machining over long periods. Modular in design, our applications can be put together in exactly the configuration you need.

A miss inside

The Berlin-based software house DCAM provides users with a tool that is easy and quick to program even for complex workpieces, ensures maximum process security and permits unsupervised machining over long periods. It only takes a few seconds to get from the grinding wheel profile to the technology and the respective properties, right to the final code for percent machine control. As part of production-related consultation, you will receive sound answers to the questions of competitiveness in machine, tool and mold making. Read full story All success stories. As a fully integrated solution or as a solo system, depending on the existing infrastructure. Perfect multi-axis machining With the multi-axis module IV - free-form EDM with guide curve, erosive grinding, indexed and simultaneous multi-sided machining and much more can be realized. In case of prior knowledge of SolidWorks, the course only lasts four days. DCAM has been a successful market player for almost 30 years. Modular in design, our applications can be put together in exactly the configuration you need. Mouse at rest - Machines at work- was one oft he motivations of this release. Test it. With our multi-axis module IV, free-form wire EDM with guide curve is now additionally available to you. Fast, flexible and, if required, also on-site at your premises.

Ideally configured for tool and mold making, machine and plant construction, extrusion tool and also prototype construction, our DCAMCUT special packages can be precisely adapted to the specific requirements of your company. In addition to integrated technology databases for all common makes of machine, the efficient solution offers extensive options for CAD data import and export. Interfaces for direct data transfer from external systems are already included as standard.

Modular in design, our applications can be put together in exactly the configuration you need. It only takes a few seconds to get from the grinding wheel profile to the technology and the respective properties, right to the final code for percent machine control. As a fully integrated solution or as a solo system, depending on the existing infrastructure. This is Mr. With DCAMCUT, we provide you with software that is easy and quick to program even for complex workpieces, ensures maximum process security and permits unsupervised machining over long periods. Read full story All success stories. In case of prior knowledge of SolidWorks, the course only lasts four days. In case of prior knowledge of SolidWorks, the course only lasts four days. The underestimated production factor. Fast, flexible and, if required, also on-site at your premises. Benefit from our experience. Perfect multi-axis machining With the multi-axis module IV - free-form EDM with guide curve, erosive grinding, indexed and simultaneous multi-sided machining and much more can be realized. Read more. Read more.

I think, that you commit an error. I can defend the position. Write to me in PM.

I thank for the information, now I will not commit such error.