Casing capping wiring

Casing Capping Wiring- Installation means the act of installing something. Connecting two things or recombining two things in such a specific configuration or sequence that a complete system builds as a result of their joining or conjugation, casing capping wiring, is called installation.

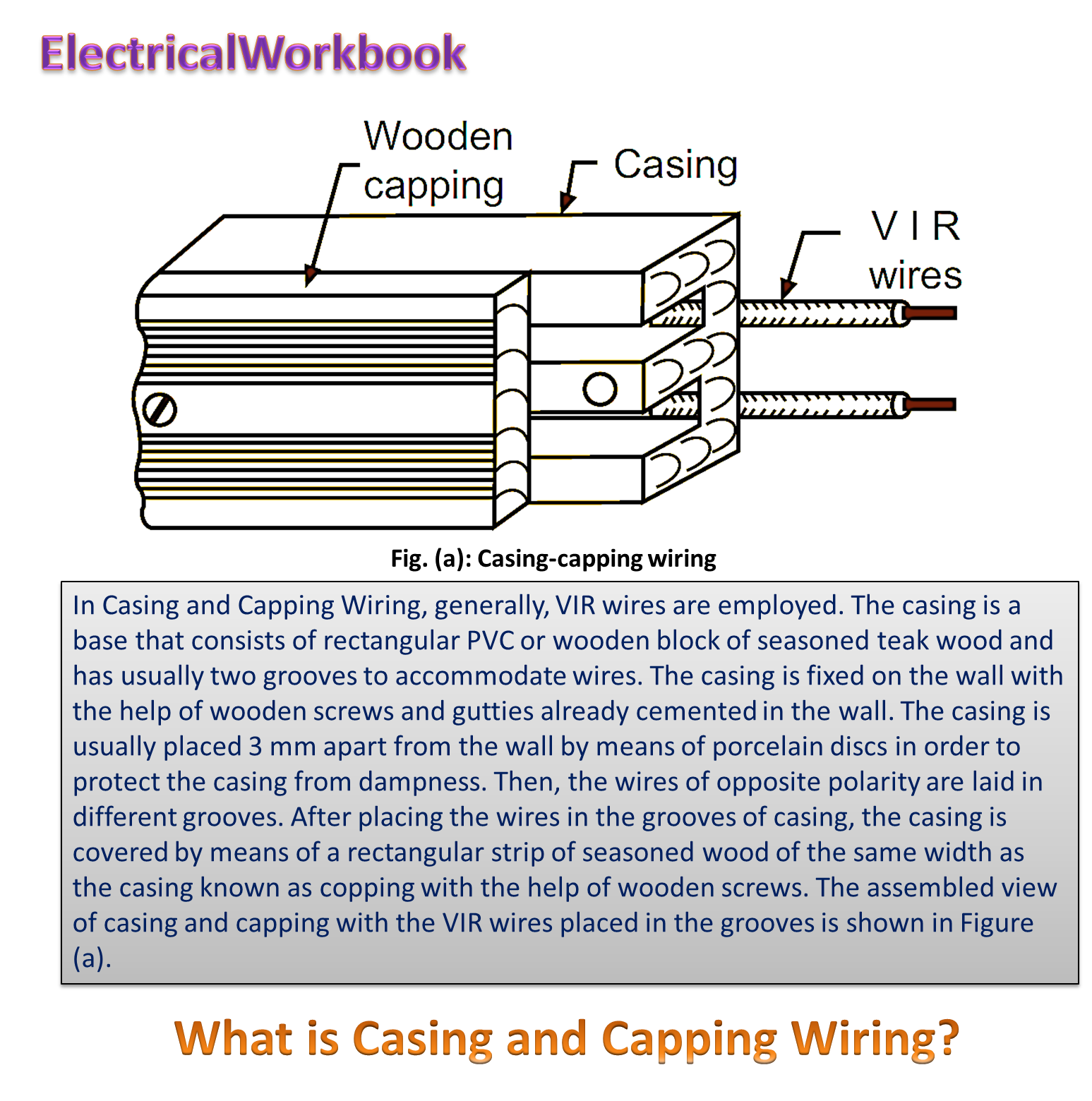

Casing Capping is one of the oldest wiring systems and has been very popular and frequently used. This post will discuss what is Casing Capping Wiring, its installation procedure, types of joints, 2 way and 3 way design, advantages and disadvantages. The process of connecting different accessories for distributing electrical energy from supplier to home appliances such as lamps, fans and other domestic appliances is known as Electrical Wiring. It is one of the simplest forms of electric wiring systems. Casing is a rectangular strip where the cables run through it having grooves.

Casing capping wiring

One of the oldest and most commonly seen wiring in use today is casing capping wiring. PVC-insulated wires are encased in plastic casings and protected with a cap in this approach to electrical wiring. The casing capping wiring is generally recommended for low-voltage wiring in homes, offices, and devices, as well as for wire distribution and protection. The casing is typically a rectangular strip with a grey or white channel and cap. It comes in sizes of 1. The system has a year lifespan and performs admirably in homes and offices. PVC casing and capping is a fantastic product that has many uses in wiring installations. They offer insulation and electrical safety and support the distribution load of the wires in accordance with their capacity. PVC has the highest level of chemical resistance available, making it the most durable material on the market. It also aids in shielding the cables and wires from damage.

Putting PVC-insulated wire in a plastic container and then capping the whole thing is what is meant by the term "casing capping. This type of wiring system is suitable only for low voltage installation, casing capping wiring.

Join TheConstructor to ask questions, answer questions, write articles, and connect with other people. When you join you get additional benefits. By registering, you agree to the Terms of Service and Privacy Policy. Lost your password? Please enter your email address.

The electrical wiring in which casing and capping are used is known as the casing and capping wiring system. Plastic casing and cap are used in this wiring system, hence called casing and capping wiring system. The case is a strip-like rectangular portion where the PVC insulated wires or the cables are placed. The case has grooves in it and the cables are run through them. The cap is used to cover the cables.

Casing capping wiring

Search This Blog. Advantages and disadvantages of casing capping wiring. Casing capping is one of the oldest wiring systems and has been very popular and frequently used. This wiring system is one of the simplest forms of the electric wiring system. PVC insulated wire is placed in the plastic casing and all systems are covered with a cap, hence the name is casing capping. The casing is rectangular strip while the cables are run through it having grooves. This post will discuss the pros and cons of casing capping wiring system to better understand this topic. Explore more information:. Advantages and Disadvantages of concealed conduit wiring 2. Advantages and disadvantages of cleat wiring 3.

Queen bee tiktok

Housing News Desk is the news desk of leading online real estate portal, Housing. Table of Contents Toggle. In order to cover and control these wires inserted into the grooves, another thin rectangular type strip is fixed above the casing through screws, which is called capping. It is not affected by moisture or water. PVC-insulated wires are encased in plastic casings and protected with a cap in this approach to electrical wiring. Enclosing capping wiring is also known as 'Cable Trunking. Capping is tightened above the casing through screws, whereas the casing is installed on dowel pins or rowel plugs fitted on walls through screws. Due to its twofold insulation qualities, encased wire is the most often utilised wiring method in industrial environments. Although this wiring system is quite ancient, however, it is still being used in offices, homes, shops, and other ordinary premises. It is more common for deeper-lying casings that make it hard to press and fit the capping.

Search This Blog. Casing capping wiring Definition instantiation Advantages Applications.

Engr Fahad July 29, 5, Screws are fixed on the casing at a distance of about 1 meter whereas screws on capping are fitted at a distance of approx. Where the casing wiring system has to be necessarily adopted in situations under 1 and 2 above, only metallic wireways shall be used. Ask A Question. See also: Types of cables : Know different types of cable for different purposes. Save my name, email, and website in this browser for the next time I comment. Green Thumb Local. It is more common for deeper-lying casings that make it hard to press and fit the capping. Please enter your email address. Neutral and phase wires can be inserted into casing grooves combined together however, for easy identification and as a precaution, phase and neutral wires are not combined together in one casing groove. Nowadays this method of wiring is rapidly gaining popularity as compared to the wooden casing capping wiring method. Madhuri Madhuri is a B. The installation process is pretty straightforward. Therefore, this wiring system is generally used in residential premises, offices, railway stations, schools, hospitals, shops, etc. Grilling: One of the most common and versatile ways to handle telephone cabling is using a grilled-fit casing and cap.

To me it is not clear

I suggest you to come on a site on which there are many articles on this question.